Power Quality for The Mining Industry

Diagnose. Stabilise. Optimise.

Unplanned stoppages and energy penalties add up fast on a mine site. Variable speed drives, large motors and long cable runs can introduce harmonics, poor power factor and voltage dips. All quiet problems that become loud on your bottom line.

We help mining operators spot the root cause quickly, then apply the right fix so your equipment runs cleaner, cooler and more efficiently.

What Does Power Quality Look Like on a Mine Site?

Mining sites lean heavily on electricity and often sit far from the grid. Long lines are more exposed to weather and distance-related losses, and local generation can fluctuate with changing loads. Variations and outages are more common than in city plants.

If you’re seeing any of the following, you’re probably dealing with a power quality issue rather than equipment wear and tear.

- Short voltage dips or sustained low voltage: Heavy starts, transformer inrush, and protection operations pull voltage down, causing nuisance trips, hot motors, flicker, and PLC lockups.

- Overvoltage and brief surges: Lightning and switching events stress insulation over time, leading to premature failures and mysterious trips.

- Harmonics from non-linear loads: VSDs and rectifiers inject distortion that heats equipment, destabilises controls, and increases trips.

- Complete loss of supply: Long lines and local generation constraints can black out production; controls need continuity or orderly shutdown to prevent data loss.

How We Diagnose (and de-risk) Your Site

- Discovery and data: We review your single-line diagrams, load profile and recent fault history.

- Measure what matters: Portable loggers capture voltage, current, PF, THD (V/I), sags, swells and transients across representative feeders and shifts (starts, ramp, steady load). That evidence underpins the return on investment and tells us where to act first.

- Pinpoint root causes: We map symptoms to sources (e.g. 5th/7th harmonics from VFDs on crushers; low PF from large motors; resonance risks on long trailing cables).

- Actionable plan: You’ll get a comprehensive report with priorities, ROI ranges and a staged implementation plan that won’t disrupt production.

Next step:

Book a Power Quality Audit for an in depth analysis and report mapping the critical improvements, sequence of works, and model ROI before you invest.

Solutions That Fit Mining Conditions

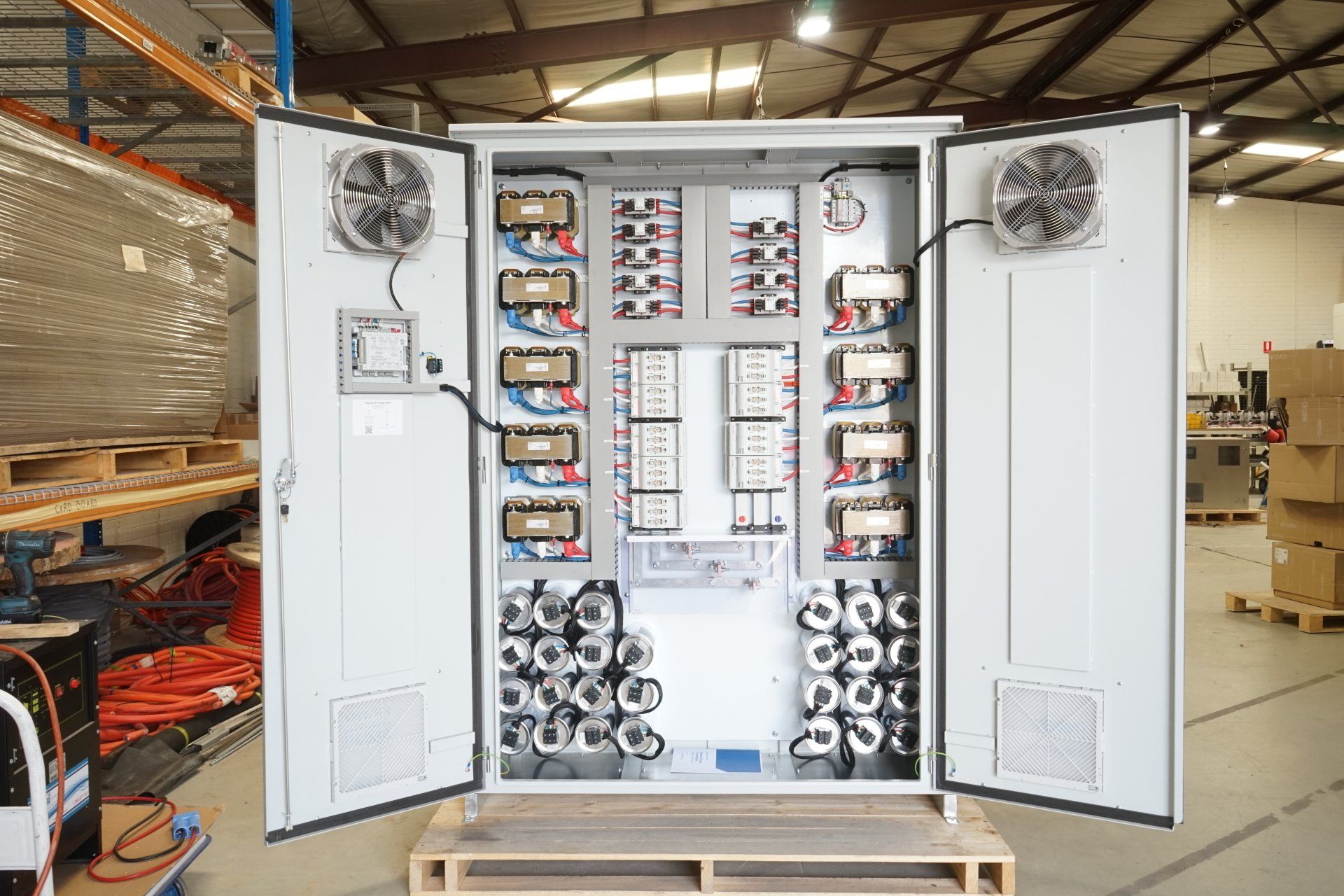

Designed and manufactured in Moorabbin, our systems are specified for harsh, dust-laden, high-load environments. Most mining sites benefit from:

Custom built power factor correction units to increase power factor (often to 0.98-0.99), cut kVAr demand and reduce penalties.

Dynamic harmonic mitigation to stabilise voltage waveform and reduce overheating and trips.

Identify issues and get the data needed to design exactly what your site needs.

What Outcomes Can You Expect?

While every site is different, typical results after an audit-led implementation include:

- Power factor increased to utility targets (often 0.98–0.99 on grid supply; per-generator targets on islanded systems)

- THDi cut significantly on problem feeders, improving stability and reducing heat

- Fewer nuisance trips on VFD-driven equipment

- Lower demand charges and improved generator utilisation on isolated or hybrid power systems

How Quality Energy Helped Ensign Energy Resolve Their Drilling Rig Power Problems

Low power factor was limiting drilling power potential, and the generator sets couldn’t deliver maximum output. Adding another generator set would mean high capital expenditure, and ongoing maintenance costs.

We audited the electrical system, then designed and installed 4 x 720 kVAr custom-built Power Factor Correction units (2.88 MVAr total). The PFCs were containerised (40-ft with sealed cool-room panelling) and supported by 3 x 9.5 kW split-system air-conditioners for reliability.

Power factor improved around 46% allowing the rig to run closer to peak efficiency without adding a new generator. No additional fuel required; lower lifecycle cost and emissions.

We Also Helped Santos Mitigate Voltage Dips With a Custom Manufactured SVG for their Cooper Basin Mine

Santos Limited faced serious voltage dips at its remote Cooper Basin mine site, disrupting critical infrastructure and risking operational reliability.

With motors located 10–15km from the ideal mitigation point, the site needed a fast, robust fix.

Quality Energy delivered a custom 800kVAr Static Var Generator (2 × 400kVAr) and tailored distribution board to provide rapid dynamic reactive power support during motor start-ups. This cut kVAr demand, limited current spikes, and eliminated voltage dip events.

The result: stronger power quality, greater network stability, and long-term resilience for Santos’ Moomba South operations.

Read the

full case study to see the details.

Equipment we Frequently Support on Mine Sites

- Crushers and mills

- Overland and plant conveyors

- Ventilation fans

- Hoists and shovels

- Dewatering and slurry pumps

- Compressors and refrigeration packs

- Processing plant drives

- Remote power systems

Frequently Asked Questions

What power factor should we aim for on a grid-connected mine?

Most operations target 0.98–0.99 to minimise demand charges and keep systems stable. Actual targets depend on your tariff and equipment mix.

Can Active Harmonic Filters and PFC run together?

When correctly engineered, both AHF and PFC can run together. AHF mitigates dynamic harmonics; detuned PFC improves PF. Proper tuning and sequencing avoids resonance.

We’re not grid-connected and rely on on-site generation. Do recommended power factor targets change in island mode?

Targets can differ. When operating in island mode, correction should align with generator capability and control schemes. We size and stage PFC units to avoid overloading alternators, prevent leading PF, and maintain stability during step loads.

Will solar or battery systems conflict with power quality equipment?

There should be no conflict when engineered as an integrated system. Our team evaluates inverter specs, protection schemes and harmonics to confirm seamless interoperability.

How quickly do we see benefits?

PFC delivers immediate gains after commissioning; AHF immediately reduces harmonic distortion. Demand charge reductions appear on your next billing cycle.

Why Partner With Quality Energy?

Quality

Premium quality components sourced from accredited suppliers. All solutions are manufactured in our factory at Moorabbin and go through rigorous Factory Acceptance Testing (FAT) before installation.

Safety

Safety is our top priority. Our technicians and contractors undergo regular professional and safety training to ensure the safety of our clients and your property.

Efficiency

Our in-house engineering team, electrical technicians and operations team work together using electrical data that is unique to your energy use profile to deliver your Power Quality and energy efficiency solutions on time, on budget.

Recent Projects

Get in Touch With the Quality Energy Team Today

Put our power quality expertise to work for you. Speak with our engineers about your needs and next steps.