Power Quality for Healthcare

Safety. Reliability. Clinical Accuracy.

In healthcare environments, power quality is not just an operational concern, it is a patient safety issue.

Hospitals, aged care facilities and medical centres rely on continuous, clean electricity to support life-saving equipment, diagnostic accuracy and essential building services. Even minor electrical disturbances, such as harmonic distortion, voltage fluctuation or nuisance tripping, can disrupt medical equipment, compromise test results or interrupt critical services.

Quality Energy helps healthcare operators identify, manage and mitigate power quality risks so clinical teams can focus on what matters most: patient care.

Why Power Quality Is Critical in Healthcare Environments

Modern healthcare facilities operate dense electrical networks with a high concentration of sensitive and non-linear loads, including:

- Medical imaging and diagnostic equipment (ECG, MRI, CT, X-ray)

- Life-support and monitoring systems

- Pathology and laboratory equipment

- HVAC and chiller plants supporting theatres and wards

- IT systems, data centres and nurse-call infrastructure

When electricity quality degrades, the impacts can be immediate and serious:

- Diagnostic inaccuracies caused by harmonic interference

- Unexpected equipment shutdowns during peak load or hot weather

- Temporary closure of clinical areas

- Accelerated wear on high-value medical assets

- Risk to patient safety if critical systems lose stability

Ensuring “clean” electricity throughout a healthcare facility is essential for compliance, reliability and trust.

Power Quality Issues That Impact Healthcare Operations

If your facility is experiencing any of the following, a power quality issue may be present:

- Unexplained shutdowns of imaging or diagnostic equipment

- Interference affecting ECG or monitoring accuracy

- Voltage fluctuation or flicker linked to chiller or lift operation

- Equipment faults that only occur during peak demand or hot days

- Harmonic distortion exceeding recommended electrical limits

These issues are often invisible without monitoring, but measurable with the right data.

How we Diagnose (and de-risk) Your Healthcare Facility

- Power quality audit and monitoring: We install high-resolution power quality monitors on key switchboards to capture voltage, current, THD, flicker, transients and load profiles under real operating conditions.

- Root-cause analysis: Our engineers identify the source of interference. Commonly variable speed drives, chillers, or shared supply paths affecting sensitive clinical zones.

- Data-driven solution design: Solutions are sized and specified based on measured data, ensuring compliance with electrical standards and the operational needs of healthcare environments.

- Care-focused implementation: Works are planned to minimise disruption to clinical services, with safety, noise control and reliability front of mind.

Power Quality Solutions for Healthcare

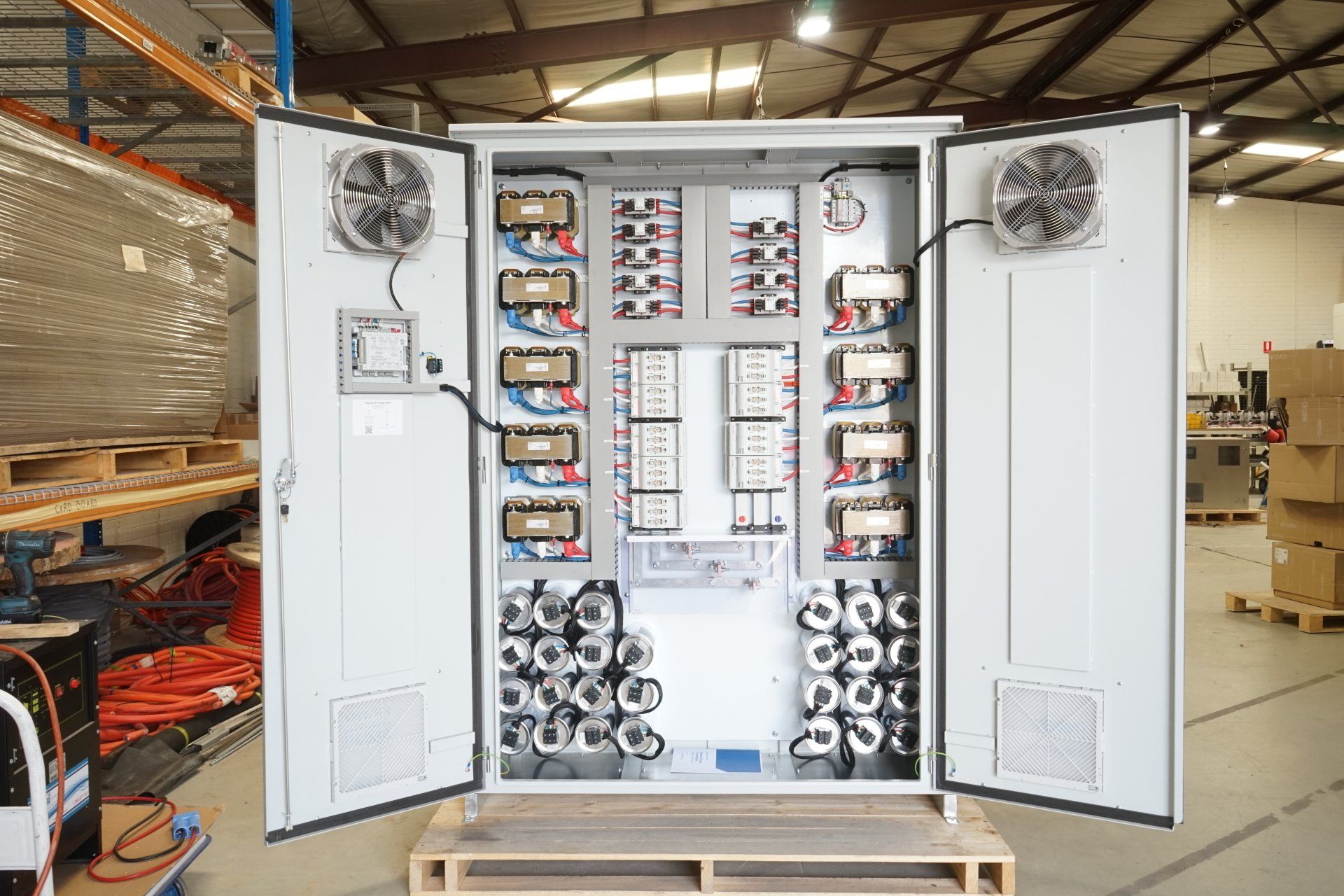

Designed and manufactured in Moorabbin, our systems are specified for high-reliability, low-noise, mission-critical environments.

Fast-acting reactive power compensation to stabilise voltage, suppress flicker and improve energy efficiency—ideal for healthcare and aged care environments where quiet, rapid response is essential.

Targeted mitigation of harmonic currents from non-linear loads (such as chillers and VSDs), protecting diagnostic accuracy and equipment longevity.

Reduces kVAr demand and improves network efficiency without compromising power quality.

Measurement-first approach to avoid unnecessary equipment spend and ensure the right fix is applied.

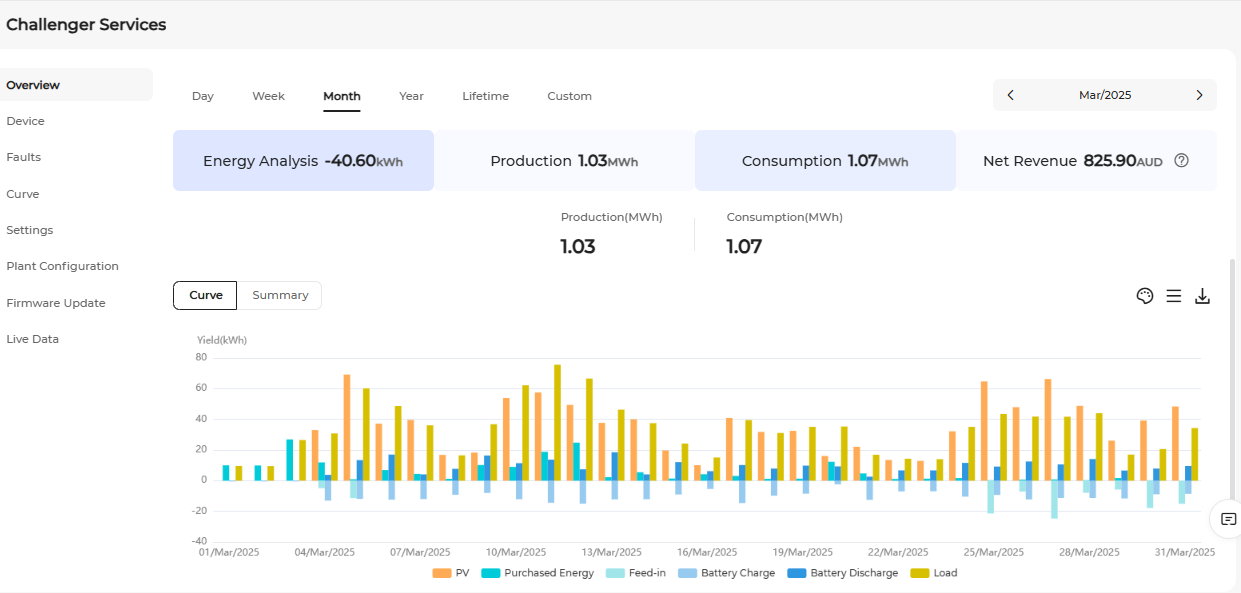

Quality Energy at Work in Australian Healthcare Facilities

Aged Care Facility Daw Park

The aged care facility operated a complex electrical network with fluctuating demand and equipment generating harmonics. Any instability in voltage or reactive power posed a risk to resident comfort, safety systems and essential services operating around the clock.

Quality Energy assessed the site’s load profile and identified the need for fast, dynamic reactive power support. We recommended and installed a 175 kVAr Static Var Generator (SVG). A low-noise solution designed to respond instantly to changes in demand and suppress voltage fluctuation and flicker.

With a response time of less than 5 milliseconds, the SVG stabilised voltage conditions, reduced power losses and improved overall energy efficiency. The facility achieved better network performance, improved return on investment and greater confidence in the reliability of its electrical supply.

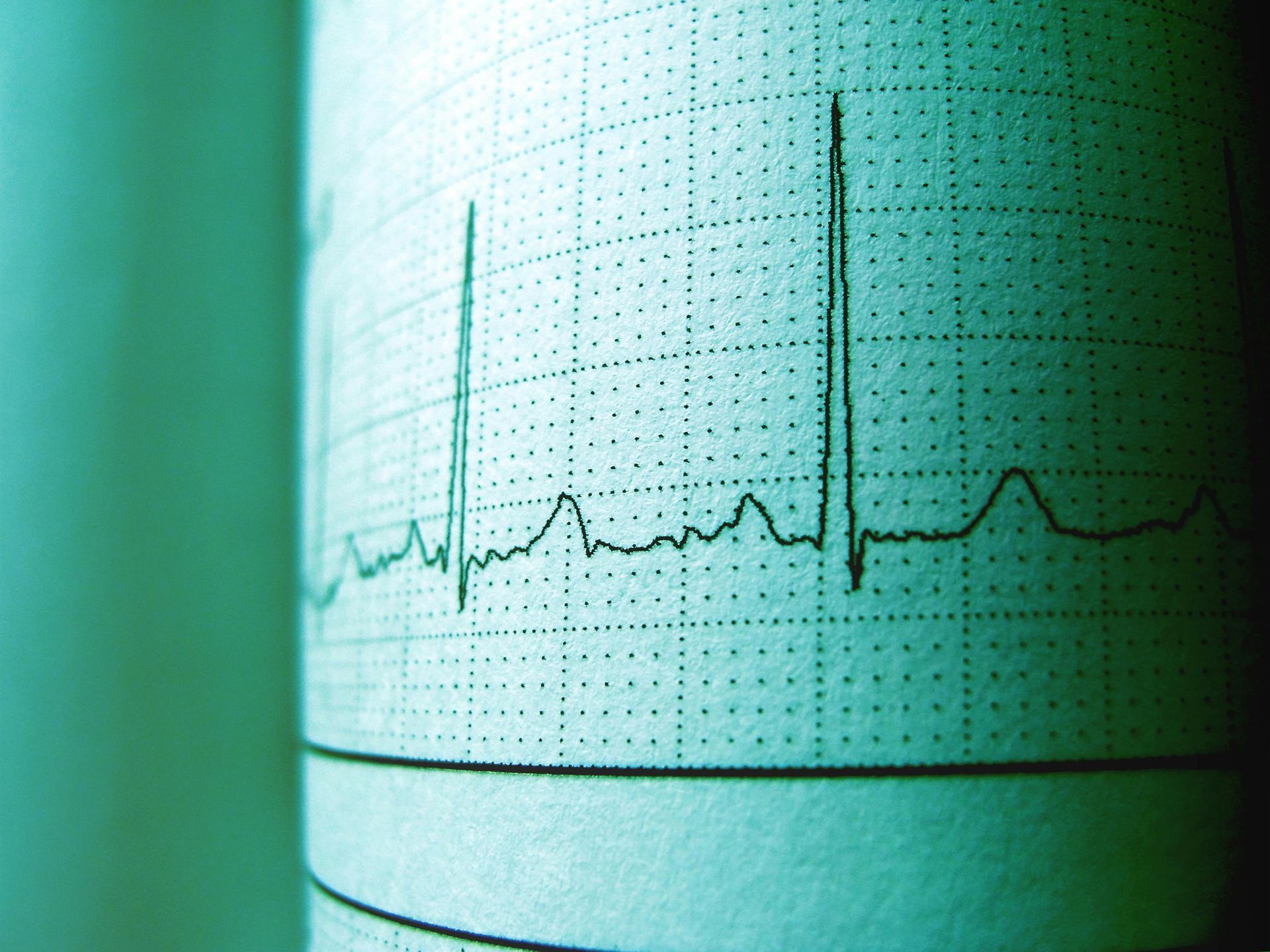

Harmonic Interference Affecting ECG Testing Solved for Royal Melbourne Hospital

Royal Melbourne Hospital experienced harmonic interference near ECG equipment in a new outpatient wing. The interference compromised test accuracy and forced the temporary closure of the ECG testing area, directly impacting patient diagnostics.

Quality Energy conducted a detailed Power Quality Audit, which revealed high levels of third-harmonic current travelling through the main supply cable feeding the area. Our engineers designed, installed and programmed two 100 Amp Active Harmonic Filters on site to address the issue at its source.

Following installation, harmonic interference was drastically reduced, allowing the hospital to safely reopen the ECG testing area. Diagnostic accuracy was restored, enabling clinicians to continue their critical, life-saving work without disruption.

Imaging Equipment Protected at Flinders Private Hospital

Flinders Private Hospital contacted Quality Energy after recurring harmonic pollution caused sensitive imaging equipment in the cancer clinic to shut down, particularly during hot weather when chiller loads were high. The issue forced the clinic to close on peak days, turning patients away.

Our in-depth power quality assessment confirmed that harmonics generated by variable speed drives controlling the hospital’s chillers were propagating through the entire electrical network. Total Harmonic Distortion (THD) levels exceeded electrical code limits and posed a serious risk to equipment health.

Quality Energy designed, manufactured and installed a custom 400 Amp Active Harmonic Filter, reducing voltage harmonic levels from 9.35% to between 1 to 3%. Delivered on time through our in-house manufacturing capability, the solution restored compliance and stability.

The result was an 89% reduction in harmonic levels, enabling the cancer clinic to operate reliably even during hot weather, protecting critical equipment and ensuring uninterrupted patient care.

Harmonic Mitigation for Ballarat Base Hospital

Stage 2 of Ballarat Base Hospital introduced a new six-storey central energy plant and support services building housing essential power, cooling, pathology and pharmacy operations. To protect continuity of services, the hospital proactively sought to understand and manage harmonic risks.

Quality Energy installed Fluke 1738 Power Quality Monitors across three main switchboards for a one-week monitoring period. The data collected provided a detailed picture of load behaviour and harmonic distortion under real operating conditions.

Using this data, our engineering team designed and manufactured a 150 Amp Active Harmonic Filter, reducing total THDi from 42-44 down to 5.

Through proactive monitoring and a data-driven solution,

Ballarat Base Hospital achieved improved reliability across essential services, long-term compliance, and confidence in the resilience of its electrical infrastructure.

Frequently Asked Questions

Why is power quality a patient safety issue in healthcare?

In healthcare settings, stable power supports safe and accurate patient care. Power quality issues can disrupt diagnostic equipment, monitoring systems and critical services. Managing power quality in healthcare environments helps reduce clinical risk.

How do harmonics affect medical equipment?

Harmonics are electrical distortions created by non-linear loads such as VSDs and UPS systems. In healthcare facilities, they can interfere with sensitive diagnostic equipment and affect accuracy. Addressing harmonic distortion in hospitals protects equipment performance.

What does a power quality audit involve in a hospital?

A hospital power quality audit focuses on measurement, not assumptions. Engineers monitor voltage, current, power factor and distortion under real operating conditions. This data-driven approach identifies risks before solutions are specified.

Why do power quality problems appear during hot weather?

Electrical demand rises during hot weather as chillers and cooling systems run continuously. This can amplify existing issues such as voltage instability or harmonics. Planning for seasonal peak demand in healthcare facilities improves reliability.

Are power quality risks different in aged care facilities?

Aged care sites often have fewer electrical redundancies. Even minor instability can affect comfort, safety systems and essential services. Proactive power quality management in aged care helps maintain a stable environment for residents.

Can power quality solutions be implemented without disrupting clinical services?

Most assessments are non-intrusive and planned around operations. Monitoring equipment is installed without interrupting supply. Solutions are staged to minimise impact on patient care and staff workflows.

How do we know which power quality solution is right for our facility?

The right solution depends on measured data. A power quality audit identifies whether issues relate to harmonics, reactive power or voltage stability. This ensures healthcare power quality solutions are correctly sized and applied only where needed.

Why partner with Quality Energy?

Quality

Premium quality components sourced from accredited suppliers. All solutions are manufactured in our factory at Moorabbin and go through rigorous Factory Acceptance Testing (FAT) before installation.

Safety

Safety is our top priority. Our technicians and contractors undergo regular professional and safety training to ensure the safety of our clients and your property.

Efficiency

Our in-house engineering team, electrical technicians and operations team work together using electrical data that is unique to your energy use profile to deliver your Power Quality and energy efficiency solutions on time, on budget.

Recent Projects

Take a Proactive Approach to Healthcare Power Quality

Book a Power Quality Audit to identify risks, prioritise corrective actions and safeguard critical healthcare operations, before issues impact patient care.