Power Quality for Commercial Buildings

Efficiency. Safety. Reliability.

In commercial buildings, power quality directly affects operational continuity, tenant satisfaction and long-term asset value.

Offices, shopping centres, schools and apartment complexes depend on stable, efficient electricity to support hundreds of electrical loads operating simultaneously. Air conditioning systems, lifts, lighting, IT infrastructure, security systems and EV chargers all draw from the same supply. When power quality deteriorates, the consequences ripple through the entire building: unexpected equipment failures, tenant complaints, inflated electricity bills and accelerated wear on critical infrastructure.

Quality Energy helps commercial building owners, facility managers and strata committees identify power quality risks and implement targeted solutions that protect building performance while reducing energy costs.

Why Power Quality Is Critical in Commercial Building Environments

Modern commercial buildings operate complex electrical networks with a high concentration of equipment that both depends on and affects power quality. HVAC systems, lifts, LED lighting, IT infrastructure, EV chargers and retail refrigeration all share the same electrical supply, and many of these loads generate harmonics or reactive power that degrades overall network performance.

When power quality deteriorates, the business impacts compound quickly. Tenant complaints escalate when lifts fault or climate control fails. Demand charges rise even when energy consumption stays flat. Equipment fails prematurely, bringing forward capital expenditure. Network operators issue compliance warnings. And transformer capacity that should support future growth gets consumed by inefficiency instead.

For building owners and facility managers, poor power quality is both an operational risk and a financial drag that often goes undiagnosed until problems become costly.

Signs Your Building May

Have a Power Quality Issue

If your building is experiencing any of the following, a power quality problem may be present:

- Circuit breakers tripping during hot weather or peak trading periods

- Lift malfunctions that occur without clear cause

- Flickering lights when chillers or compressors cycle

- Overheating in transformers, switchboards or distribution boards

- Rising demand charges despite stable energy consumption

- Network operator warnings about harmonics or power factor

These issues are measurable with the right monitoring equipment. A Power Quality Audit identifies exactly what's happening and where.

How We Diagnose (and De-Risk) Your Commercial Building

- Power quality audit and monitoring: We install high-resolution power quality monitors on main switchboards and distribution boards to capture voltage, current, THD, power factor, flicker and load profiles under real operating conditions across different times of day and seasons.

- Root-cause analysis: Our engineers identify the source of power quality issues. Common culprits in commercial buildings include variable speed drives on HVAC systems, lift motors, LED driver harmonics and EV charger loads.

- Data-driven solution design: Solutions are sized and specified based on measured data, ensuring the right fix is applied where it's needed. This avoids over-engineering and ensures compliance with network operator requirements.

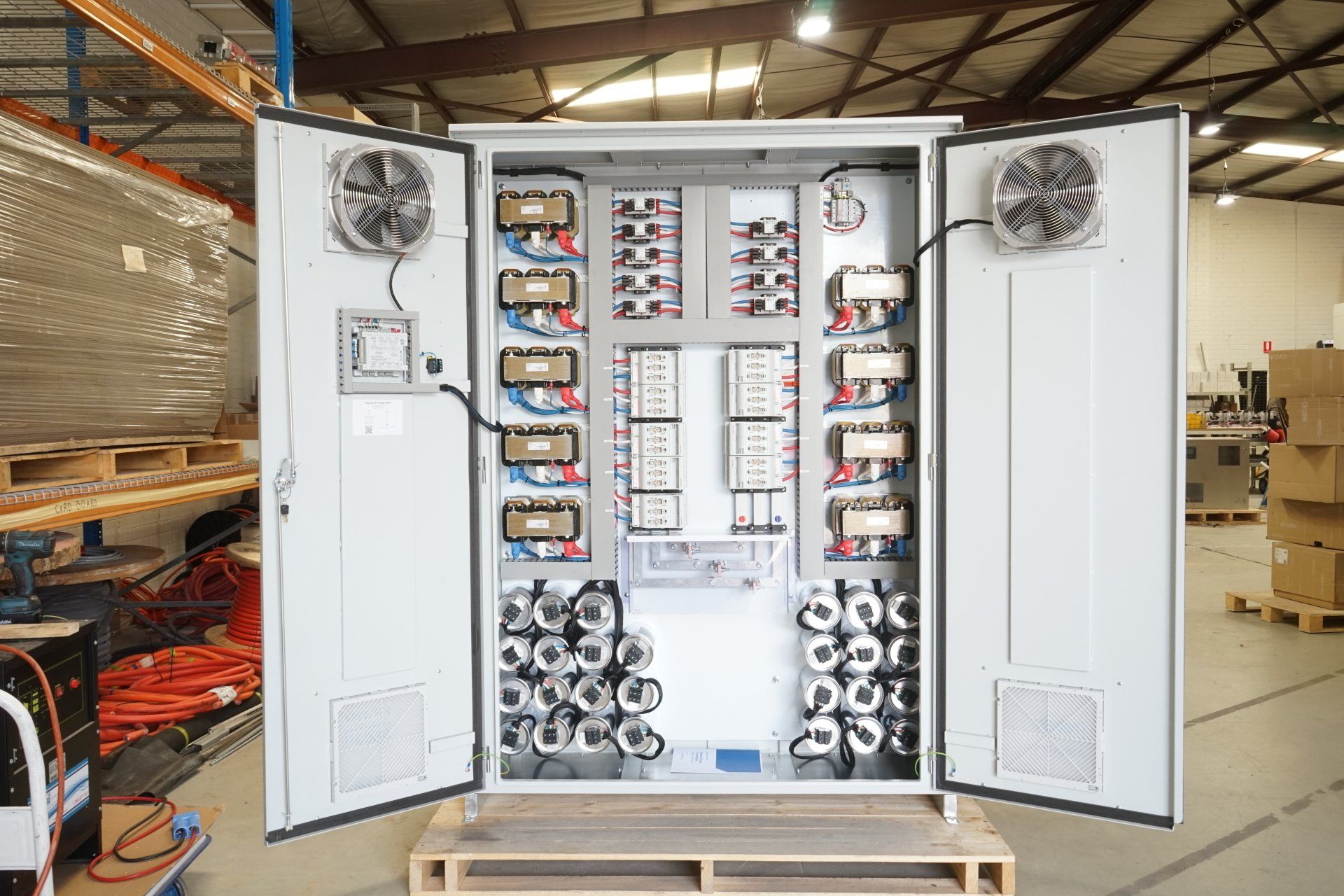

- Minimal disruption implementation: Works are planned around building operations and tenant schedules. Equipment is manufactured and tested at our Moorabbin factory before arriving on site, reducing installation time and risk.

Power Quality Solutions for

Commercial Buildings

Designed and manufactured in Moorabbin, our systems are built for reliability and long-term performance in demanding commercial environments.

Power Factor Correction (PFC)

Reduces reactive power (kVAr) demand to lower electricity bills and free up network capacity. Our ECO and MOD

PFC systems range from 50kVAr to 1000kVAr and are custom-designed for each building's load profile.

Static Var Generators (SVG)

Fast-acting

reactive power compensation that stabilises voltage, suppresses flicker and responds instantly to load changes. Ideal for buildings with lifts, chillers or other equipment causing voltage fluctuation.

Power Quality Auditing

A measurement-first approach that identifies exactly where issues originate and what solution delivers the best return on investment. Avoids unnecessary equipment spend.

Quality Energy at Work in

Australian Commercial Buildings

Power Factor Correction for a Major WA Shopping Centre

Rockingham Centre, a major shopping and entertainment hub owned by Vicinity Centres, was experiencing a poor power factor that was driving up demand charges across their 135+ store complex.

Quality Energy assessed the site's electrical load profile and designed a custom Power Factor Correction unit manufactured at our Moorabbin factory. The solution was sized to handle the centre's variable demand patterns, from quiet weekday mornings to peak weekend trading.

Following installation, power factor improved significantly, reducing demand charges and improving the overall efficiency of the centre's electrical network.

Reducing Harmonic Distortion at Highpoint Shopping Centre

Highpoint Shopping Centre was experiencing harmonic distortion levels that exceeded the electrical network's code limits. The issue was traced to the high concentration of non-linear loads across the centre's retail and food court areas.

Quality Energy was engaged to design and manufacture a custom Active Harmonic Filter solution. Our engineers analysed the harmonic spectrum and designed a system that targeted the specific harmonic orders causing the issue.

The result was full compliance with network harmonic limits and improved power quality across the entire shopping centre.

Active Harmonic Filter Keeps Rialto Towers Cooling System Compliant

Melbourne's Rialto building experienced voltage surges and unplanned lift outages that were affecting tenant experience and building operations. Investigation revealed voltage instability linked to the building's chiller plant and lift systems.

Quality Energy conducted a detailed power quality audit and designed an Active Harmonic Filter solution to address the root cause. The system stabilised voltage conditions and eliminated the lift faults.

The regeneration project also included investment in technology and energy infrastructure, cementing Rialto's position as a premium business address with reliable building services.

University of Melbourne Power Factor Correction

When CitiPower/Powercor moved to kVA network tariffs in 2016, the University of Melbourne's electricity charges increased significantly due to inefficient electrical systems and poor power factor.

Quality Energy designed and installed Power Factor Correction equipment across multiple campus buildings, bringing power factor to efficient levels and reducing demand charges. The university continues to partner with Quality Energy to manage power quality across their Melbourne campus.

Frequently Asked Questions

Why are my building's electricity demand charges increasing?

Demand charges are based on the peak kVA your building draws from the network. Poor power factor means your building draws more apparent power than it actually uses, inflating demand charges. Power Factor Correction reduces reactive power demand and can significantly lower these charges.

What causes harmonic distortion in commercial buildings?

Harmonics are generated by non-linear electrical loads. In commercial buildings, common sources include variable speed drives on HVAC systems, LED lighting drivers, UPS systems, EV chargers and IT equipment. High harmonic levels can affect sensitive equipment and exceed network compliance limits.

How do I know if my building has a power quality problem?

Signs include unexplained equipment failures, circuit breaker trips during peak demand, flickering lights, overheating switchboards, and rising demand charges. A Power Quality Audit provides measured data to identify exactly what's happening and where.

Will power quality equipment disrupt building operations during installation?

Most Power Quality Audits are completely non-intrusive. Equipment is manufactured and tested at our Moorabbin factory before delivery, minimising on-site work. Installation is planned around building operations and tenant schedules.

How long does it take to see savings from Power Factor Correction?

Savings appear on your next electricity bill after commissioning. Most commercial buildings see payback periods of 12 to 24 months depending on the size of the installation and the existing power factor.

Can power quality issues affect my building's transformer capacity?

Poor power factor and harmonic distortion both reduce the usable capacity of transformers and switchboards. Improving power quality can free up capacity for additional loads without costly infrastructure upgrades.

Is power quality equipment noisy?

Our equipment is designed for commercial environments where noise matters. Static Var Generators in particular are selected for low-noise operation in buildings where quiet performance is essential.

How often does Power Factor Correction equipment need servicing?

We recommend annual PFC equipment servicing to check capacitor health, contactor condition and controller settings. Regular servicing extends equipment life and maintains optimal performance. Quality Energy provides servicing for both our own equipment and third-party installations.

Why partner with

Quality Energy?

Quality

Premium quality components sourced from accredited suppliers. All solutions are manufactured in our factory at Moorabbin and go through rigorous Factory Acceptance Testing (FAT) before installation.

Safety

Safety is our top priority. Our technicians and contractors undergo regular professional and safety training to ensure the safety of our clients and your property.

Efficiency

Our in-house engineering team, electrical technicians and operations team work together using electrical data that is unique to your energy use profile to deliver your Power Quality and energy efficiency solutions on time, on budget.

Recent Projects

Take a Proactive Approach to Commercial Building Power Quality

Book a Power Quality Audit to identify risks, prioritise corrective actions and protect your building's electrical infrastructure before issues affect tenants and operations.