Static Var Generator: Power Quality for Modern Businesses

Revolutionising Power Quality with High-Efficiency SVGs for Safer, More Efficient Energy Solutions

At Quality Energy, we manufacture world-leading Static Var Generators (SVGs) to address challenges like reactive power imbalances, improving power factor, stabilising voltage, and strengthening overall power quality. SVGs compensate for dynamic reactive power imbalances, ensuring better grid voltage stability.

With 35 years of expertise, we provide tailored solutions to Australian businesses including custom Low Voltage (LV) and High Voltage (HV) Power Factor Correction solutions for industrial and commercial settings.

If increasing energy costs, low power factor, and voltage instability affect your business, our Static Var Generators are here to help.

What is a Static Var Generator (SVG)?

A Static Var Generator (SVG) is a modern power electronics-based device that provides real-time reactive power compensation. Connected in parallel with your electrical system, it detects and corrects reactive power imbalances caused by your load. A SVG dynamically adjusts the phase angle of current to stabilise voltage, improve power factor, and eliminate inefficiencies.

Unlike older static electricity generators (such as compensators or capacitor banks), SVGs adapt dynamically to changing loads without excessive interventions. They offer lightning-fast compensation with no risk of resonance, reduced harmonic distortions, and zero ongoing maintenance.

Here’s how SVGs works to improve your power system:

- SVGs detect whether the load generates an inductive or capacitive current in real-time and corrects these imbalances dynamically.

- The SVG detects the phase angle in real-time and injects corrective leading or lagging current to maintain near-unity power factor.

- SVGs actively adjust the current, whether it lags or leads the voltage, to prevent inefficiencies caused by unbalanced systems, especially under dynamic loads.

Static Var Generators are installed alongside your inverter-powered equipment and compensate for unbalanced load current to ensure smooth, efficient operations.

How SVG Technology Improves Electric Power Performance

Introducing a Static Var Generator into your power system ensures your facility benefits from a stable and reliable electric power supply. Whether operating in high-voltage systems or dealing with complex reactive loads, SVG ensures efficient operations by addressing poor power factors and correcting voltage instability.

Read our blog post to learn more about Static Var Generators.

Why Invest in Quality Energy’s Static Var Generators?

As Australia’s leading power factor correction specialist, we have been helping businesses optimise their power systems for over 35 years. With decades of experience in power quality solutions, Quality Energy delivers custom-engineered SVG systems built to meet the unique challenges of modern Australian industries.

Our Static Var Generators Are Scalable, High Efficiency and Maintenance Free

(and manufactured here in Melbourne)

- Dynamic Reactive Power Compensation: Rapid response time (<= 5ms) for fluctuating and highly dynamic loads.

- High Efficiency: Reduced energy losses, lowered operational costs, and optimised system performance.

- Advanced Harmonic Filtering suppresses harmonic distortions, prolongs the lifespan of connected machinery, and improves system reliability.

- Scalable Solutions: Wall-mounted and free-standing modular designs fit seamlessly into any environment.

- Maintenance-Free Design: Unlike contactor-based solutions, SVGs have no moving parts, ensuring zero maintenance and greater reliability.

- Meets Australian Standards: Proven and certified to deliver reliable results under Australian grid conditions.

Quality Energy’s innovative Static Var Generator (SVG) technology is an entirely new approach to power factor correction. This technology improves the user’s system and makes THDi <5%, power factor level to 0.99, with a three-phase balance to achieve a perfect and efficient power system.

Whether your system requires compensation for capacitive reactive power or inductive reactive power, SVG provides precise, real-time corrections.

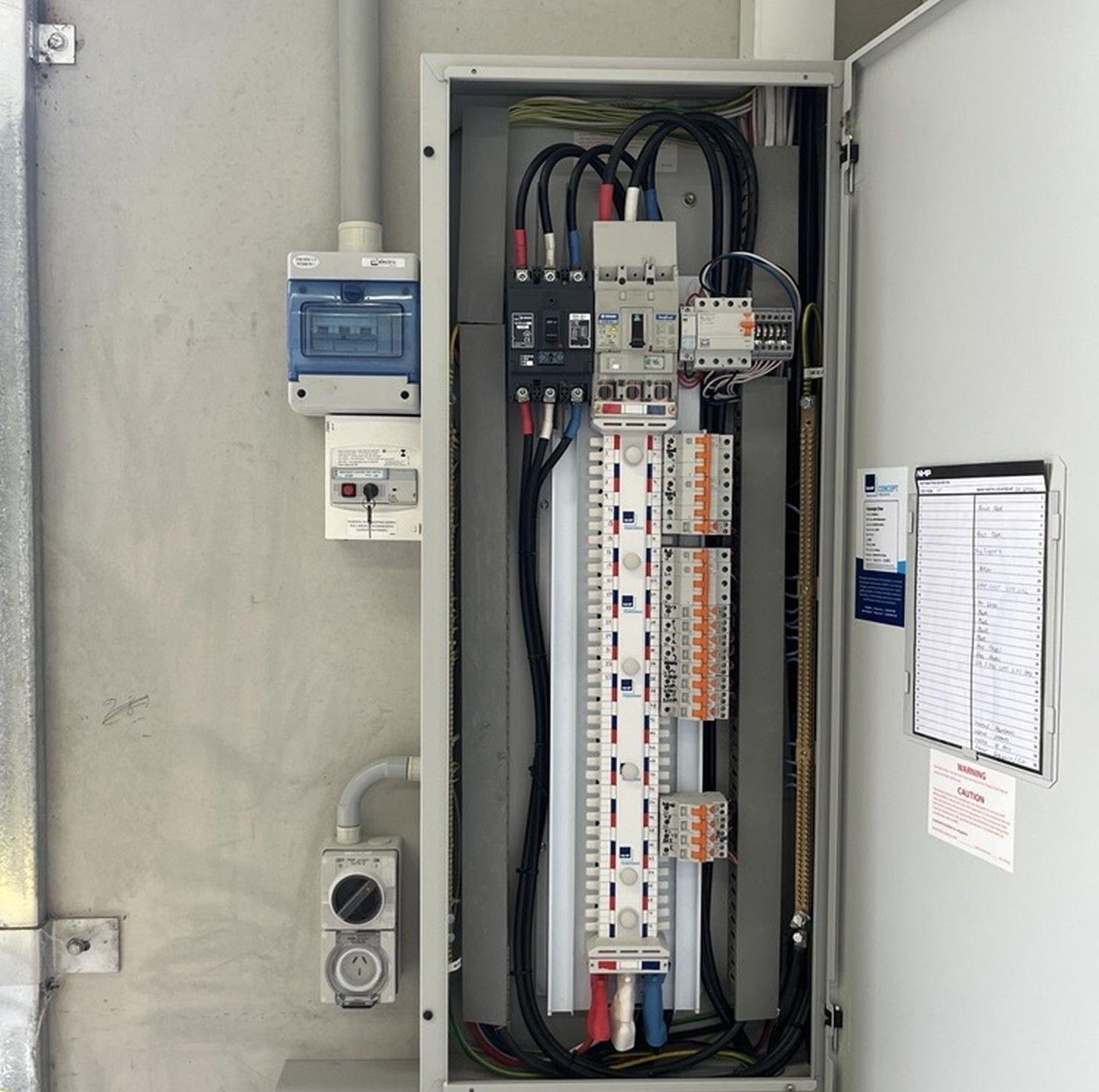

Take a Look at Some of the Static Var Generators Manufactured and Installed in Australia by Quality Energy:

A SVG Solves Your Power Quality Challenges

Real-Time Power Factor Correction

A poor power factor means higher electricity bills and wasted energy. Our Static Var Generators correct disturbances caused by harmonic currents, ensuring a consistent fundamental power factor close to unity (0.99). The outcome: lower energy bills, increased system capacity, and compliance with grid efficiency requirements.

Voltage

Stability

Dynamic loads, such as variable-frequency drives (VFDs), can create sudden fluctuations in voltage. SVG technology detects and corrects these imbalances in real-time, ensuring consistent voltage levels on the transformer side and across your system. By stabilising voltage, a SVG protects sensitive equipment, minimises downtime, and ensures safe, uninterrupted operations.

Harmonic

Mitigation

Harmonics generated by modern machinery, such as motors and UPS systems, can severely impact your electric power system by causing inefficiencies and potentially damage equipment. The SVG identifies and suppresses harmonic currents caused by modern industrial loads, such as motors or transformers. Our advanced SVG acts as a superior active power filter, detecting and correcting waveform distortions in real-time. By mitigating harmonics, the SVG improves power quality, extends the lifespan of your equipment, and ensures compliance with strict grid standards.

Load

Balancing

Unbalanced phase currents lead to overloading and inefficiencies for facilities with three-phase power. SVGs dynamically redistribute currents across all three phases to reduce stress on your infrastructure, free up system capacity, and save money on energy bills. The SVG reduces unnecessary apparent power consumption, ensuring your systems only draw the energy they need.

Is a Static Var Generator Right for My Industry?

Quality Energy integrates Static Var Generators in industries with high energy demands, complex load requirements, and modern electrical systems, including:

- Industrial Manufacturing: Industries such as automotive, food processing, and steel plants benefit from SVG’s rapid compensation for changing load demands.

- Data Centres: Stabilising bus voltage and improving energy efficiency in data-sensitive environments keeps critical power systems running efficiently.

- Heavy Industrial Loads: Solve power quality problems in metal processing and petrochemical industries caused by harmonic distortions and variable loads.

- Renewable Energy: Compensate voltage fluctuations to integrate solar farms and wind turbines into the grid seamlessly.

- Smart Commercial Buildings: Avoid penalties for poor power factor while ensuring compliance with regulatory power quality standards.

As a power correction specialist with over 35 years of expertise, we ensure industry-leading solutions tailored for your facility. Our free standing or wall-mounted SVG modules can be tailored to save valuable space while delivering high-performance power quality correction.

Client: BE Switchcraft, South Australia

Industry: Aged Care - Hammond Care

Solution: 175 kVAr Static Var Generator

Outcome: This project resolved harmonic energy issues while reducing energy costs for the aged care facility. The SVG delivered low-noise operation, improved energy efficiency, and ensured dynamic power factor correction for fluctuating load needs.

Why Choose Quality Energy for Your Static Var Generator?

Decades of Expertise

As a pioneer in power quality solutions, we proudly manufacture All bespoke SVG systems in our Melbourne-based facility, ensuring premium quality and performance. Focusing on reliability and sustainability, we provide solutions tailored to your industry.

Certified Performance

We design and test all products to meet international standards. Safety, reliability, and long-term performance are at the core of our business.

Turnkey Solutions

From design to installation, our Static Var Generators are delivered pre-configured with mounting hardware, current transformers, and integration support.

Energy Bill Savings

By optimising your system with a Static Var Generator, you can free up capacity, avoid penalties for poor power factor, and reduce consumption-related costs.

Advanced Static Var Generator Features for Superior Power Quality

Product Features:

- Three-level topology

- Ultra-compact modular design

- Fast switching frequency 25.6kHz

- Low power consumption $2.5%

- Leading dissipation technology

- Continuous Power Factor Correction

- Precise Power Factor maintain -1.0 ≤ Cos ≤1.0

- Both capacitive and inductive control

- No over or under-compensation

- Hybrid Power Factor Correction

- Three-phase loading balance

- Low noise

What our customers say

Related articles

Take the Next Step Toward Energy Efficiency

Don’t let poor power quality affect your operations. The journey to optimising your electric power systems starts with a Power Quality Audit from the experts at Quality Energy.

Contact us today to explore how our Static Var Generator solutions can transform your business, reduce costs, and ensure compliance with industry standards.

Looking to get expert advice? Fill in your details below and we'll get right back to you.

We respect your privacy