Preventative Maintenance

Prevent unexpected power disruptions, faults and hazards with preventative and maintenance, servicing and repairs.

Avoid unplanned shutdowns due to equipment failure with a proactive power quality or renewable energy maintenance program tailored to your site. Our skilled and certified electricians specialise in Preventative Maintenance for Power Factor Correction (PFC), Active Harmonic Filters (AHF), Static Var Generators (SVG), and solar PV systems. We handle everything from servicing and repairs to maintenance and replacements for both our equipment and third-party systems. Stay ahead of potential issues and keep your operations running smoothly with our comprehensive solutions!

Why Preventative Maintenance?

'Run-to-fail' or a Reactive Maintenance strategy can cost up to eight times more than having a Preventative Maintenance strategy.

While equipment failures cannot be eliminated, it is possible to reduce them and prolong the lifespan of your expensive power quality equipment or solar PV system, in turn saving money in the long run.

What does Preventative Maintenance involve?

Preventative Maintenance involves the planning and scheduling of maintenance on critical equipment and identifying and eliminating potential problems before they arise.

Preventative Maintenance can be a complex process, which is why it is important to select the right electricians specialised in this area to carry out the works.

Our Services

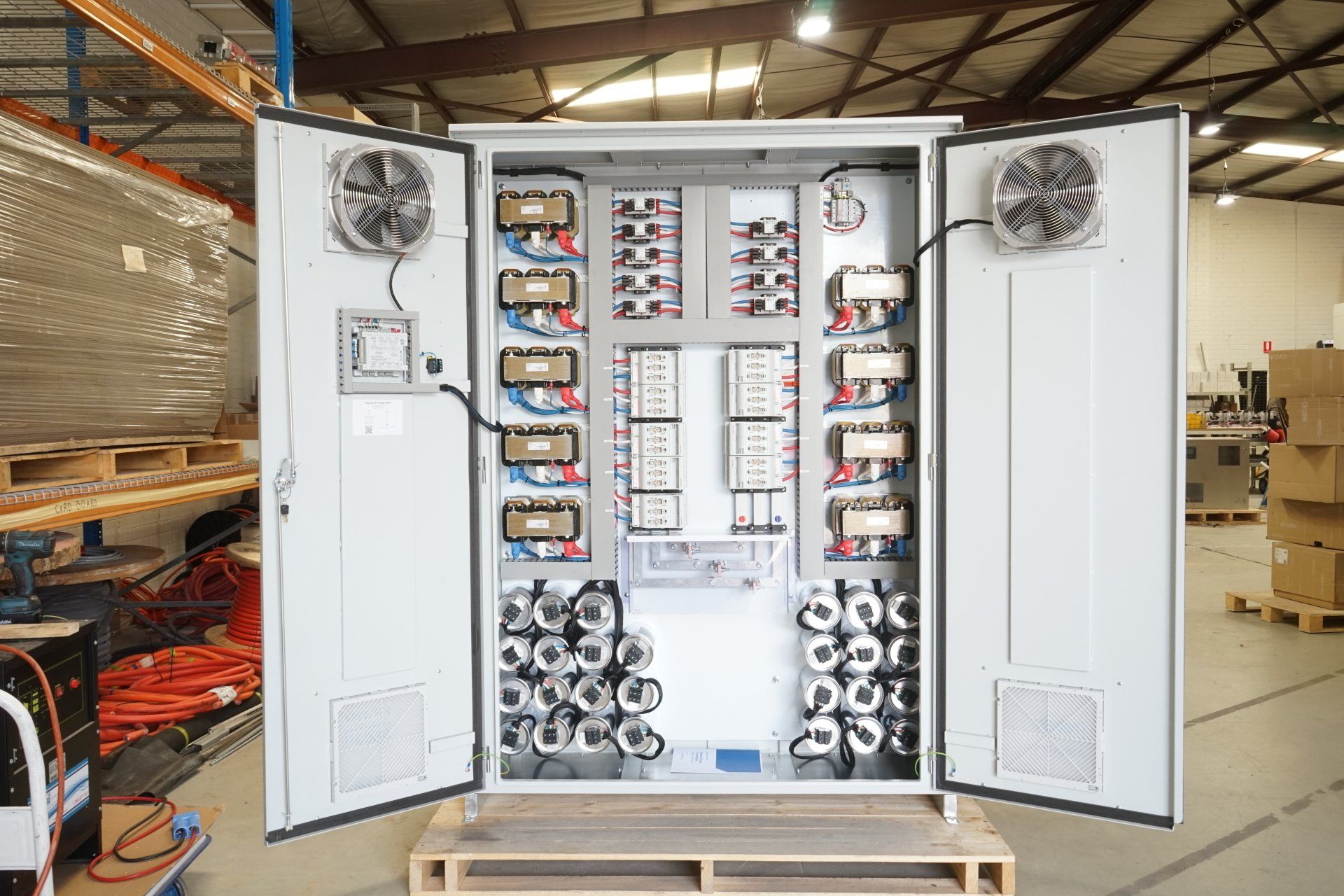

Power Factor Correction (PFC) Servicing

Like a car, Power Factor Correction System also requires routine maintenance to ensure all components are working to the highest efficiency. All PFC components are checked and serviced, and filters are replaced if necessary to protect your PFC system. or more details on servicing and repairs, click here.

Active Harmonic Filter (AHF) Servicing

Over time, electrical components contained in an Active Harmonic Filter may deteriorate from environmental conditions such as heat and moisture or dirt or dust could accumulate. To keep your Active Harmonic Filter's performance optimal, make an appointment with our team for an Active Harmonic Filter service. For more details on servicing and repairs, click here.

Static Var Generator (SVG) Servicing

Static Var Generators are fairly new technology, so you shouldn't trust just anyone to provide servicing, maintenance or repairs. Trust the company that manufactures and knows SVGs inside out. Quality Energy can conduct a visual inspection to identify any issues, attend to any issues if necessary, clean if required, test the system to confirm functionality and more. Keep your SVG's performance optimal, make a service appointment with our team today.

Solar PV System Servicing

Regular solar PV system servicing, maintenance and cleaning ensure that any faults or potential issues are promptly addressed and allow for continuous maximum solar output. Our solar experts can provide thorough inspection, clean and maintenance services on a one-off basis, or as part of a bi-annual or annual schedule. For more information, click here.

The Quality Energy Promise

Safety, integrity and quality are our top priorities.

Our commitment to excellence has won us the Manufacturing and Construction Award by the Gold Coast Business Excellence Awards Committee in 2016.

- We love our customers - no job is too big or small for us. It's what makes us the preferred service provider for big and small businesses for more than 35 years.

- Fully licensed and insured - our electricians are fully qualified and insured to carry out jobs on-site.

- Excellent customer service - Our in-house customer service team provides you with a single point of contact for bookings and billings.

- National project management - our dedicated operations team coordinate and manage all facets of your job, from ordering to installation and reporting, so you can focus on your core business.

What our customers say

Related articles

Is your business suffering from unexplained electrical faults, failures or power spikes?

A power quality audit will identify issues and give us the data we need to design an appropriate solution for your business.

Looking to get expert advice? Fill in your details below and we'll get right back to you.

We respect your privacy