Power Factor Correction Servicing Australia

Service and repair your Power Factor Correction to protect your equipment and ensure your PFC is operating at its maximum efficiency.

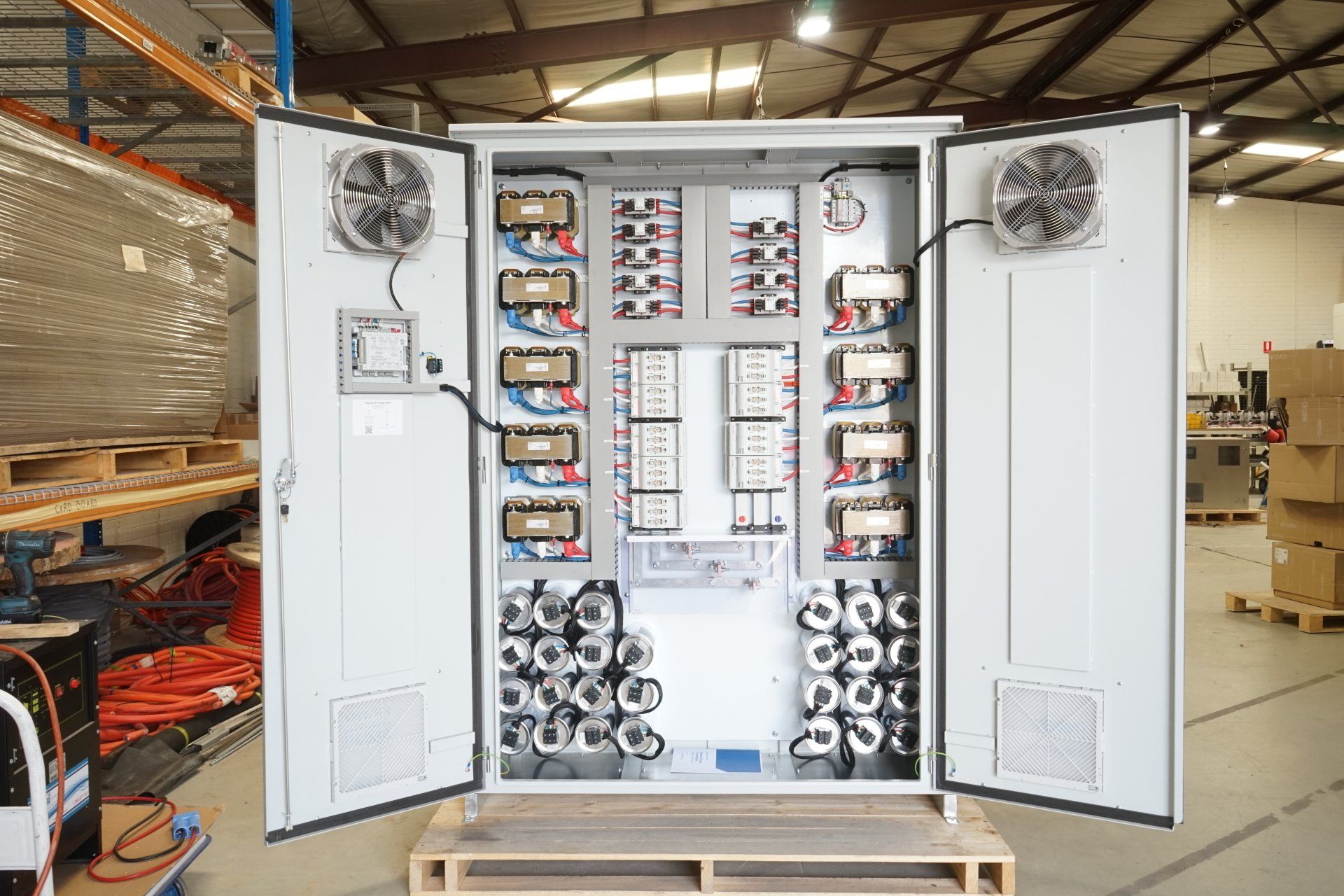

At Quality Energy, we specialise in Power Factor Correction (PFC) servicing and maintenance to help businesses reduce electricity costs, improve power efficiency, and prevent unexpected failures.

Our experts ensure your PFC unit operates at peak performance, preventing power wastage and reducing reactive power charges from energy providers.

Need emergency service?

Our custom-built PFC equipment, designed and manufactured in Melbourne, is used nationwide and internationally, serving industries such as manufacturing, healthcare, data centres, and commercial infrastructure. However, like any high-performance electrical equipment, it requires regular maintenance to maintain effectiveness.

We provide ongoing servicing,

maintenance, and repairs—both for our in house designed and manufactured power factor correction units, as well as third-party systems.

Working with us keeps your facility operating at peak efficiency. Our team is experienced in servicing a wide range of PFC units from various manufacturers, for seamless integrations and optimal performance regardless of the brand.

Our expertise, tailored approach, and commitment to exceptional service has fostered strong, long-standing relationships with our clients built on trust. Book your power factor correction servicing today and experience the difference working with Quality Energy can make to your operations.

Signs Your Power Factor Correction Unit Needs Servicing

A poorly maintained PFC unit gradually loses efficiency, leading to:

- Increased reactive power (kVAr).

- Higher maximum demand charges (kVA) from electricity providers.

- Greater system losses, reducing active power savings.

PFC units are designed to run 24/7 and need annual servicing and maintenance to keep their performance optimised. If you haven’t had your PFC serviced regularly, you may get these warning signs:

- Unexpected increases in energy bills

- Frequent circuit breaker trips or power factor penalties

- Burnt or overheated capacitor banks

- Unusual noises from the PFC unit

- Visible dust accumulation or airflow blockages

If you experience any of these issues, schedule your power factor equipment servicing with Quality Energy today. We work with on-site engineers, electricians and contractors. We will identify the cause of the issues and take steps to rectify them. For our interstate clients, initial consultations can happen over the phone to determine whether or not a call out is necessary.

Power Factor Correction Failure: A Preventable Disaster

Our team was called to inspect this PFC unit at a large shopping centre, only to find it had completely burned out. Upon closer inspection, it became evident that the system had suffered from years of neglect, leading to overloaded capacitors, failing contactors, and excessive heat buildup—ultimately resulting in a fire that destroyed the unit.

The Consequences of Neglected PFC Maintenance:

- Higher Electricity Bills: Without a functioning PFC unit, businesses incur power factor penalties and increased demand charges.

- Severe Fire Hazards: Heat buildup in failing capacitors or contactors can cause electrical fires, endangering property and lives.

- Costly Downtime and Repairs: Once a PFC unit reaches this level of failure, replacement is the only option, leading to unnecessary expenses and business disruptions.

Don’t let this happen to you! Our expert technicians can inspect, maintain, and repair your PFC unit before disaster strikes.

Book your power factor correction inspection

and service by Quality Energy today.

What’s Included in Our Power Factor Correction Servicing?

At

Quality Energy, our PFC servicing and maintenance covers:

System Diagnostics and Data Download

Downloading system logs to detect power factor trends and inefficiencies.

Analysing load profiles for variations affecting performance.

Thermal Imaging and Component Inspection

Infrared thermal scanning to identify overheating joints and capacitor failures.

Visual inspection of capacitor banks, reactors, and connections.

Electrical Testing and Preventative Maintenance

Harmonic distortion analysis (THD diagnostic).

Capacitor discharge and insulation resistance testing.

Contactor relay examination and electrical joint tightening.

Cleaning and Airflow Optimisation

Dust removal from air filters and ventilation systems.

Air filter replacement as needed.

Cleaning electrical components to prevent overheating.

Full System Performance Report

A detailed report with graphical insights showing your unit’s health.

Expert recommendations on upgrades or repairs if needed.

Our Long-Term PFC Maintenance and Compliance Audits

As one of the few power factor correction equipment manufacturers in Australia. We know PFC inside out, and can assist with:

- Bi-annual and annual preventative maintenance contracts

- Energy compliance reports aligned with Australian Electricity Regulations (NER, AS/NZS 61000).

- Upgrades to Smart Power Factor Controllers for automated efficiency.

A well-maintained PFC unit can pay for itself in energy savings within 6-12 months, but the benefits don’t stop there.

By scheduling long-term, worry-free PFC servicing, facility managers can take a set-it-and-forget-it approach, ensuring consistent savings and minimising downtime - without the hassle of reactive repairs.

Industries We Serve

- Manufacturing and Heavy Industry

- Commercial Buildings and Shopping Centres

- Hospitals and Healthcare Facilities

- Mining and Processing Plants

- Data Centres, IT Infrastructure, Schools and Universities

- Food and Beverage Processing

Contact us today for a tailored power factor correction servicing plan, and let us take care of your annual maintenance.

Stay Ahead of Failures and Protect Your Operations with Expert PFC Servicing

Unexpected downtime, rising energy costs, and electrical failures don’t have to be part of your future. With Quality Energy’s expert PFC servicing, you’ll keep your units running efficiently.

Let our team handle everything, so you can focus on what matters most. Book your PFC inspection now and experience the long-term benefits of worry-free maintenance.

What our customers say

Related articles

Is your business suffering from unexplained electrical faults, failures or power spikes?

A power quality audit will identify issues and give us the data we need to design an appropriate solution for your business.

We respect your privacy

By submitting this form you agree to be contacted by Quality Energy about our products and services. Occasionally, Quality Energy will send marketing information and offers about our products and services via email. Please contact us if you wish to opt-out of our marketing emails. For more information about how we use your information, please see our Privacy Policy.