Power Quality for Australian Agriculture

Irrigation failures, cold storage trips and processing downtime cut directly into margins on the farm. Variable speed drives, large pumps and extended rural power lines can introduce harmonics, poor power factor and voltage instability. All quiet problems that become expensive fast.

We help agricultural operators identify the root cause quickly, then apply the right solution so your equipment runs reliably, efficiently and within grid compliance.

What Does Power Quality Look Like on Australian Farms?

Agricultural operations depend on consistent electricity supply but often sit at the end of long rural feeders. Extended distribution lines are vulnerable to weather events, voltage drop and supply fluctuations, while on-farm generation (solar, diesel) adds complexity to power management. Variations that would barely register in urban areas can shut down critical irrigation or cold storage systems.

If you're seeing any of the following, you're likely dealing with a power quality issue rather than aging equipment or maintenance problems.

- Short voltage dips or sustained low voltage: Pump starts, irrigation system ramp-ups and transformer switching pull voltage down, causing nuisance trips on VSD pumps, overheating motors, flickering lights and controller resets.

- Overvoltage and brief surges: Lightning strikes on exposed rural lines and switching transients stress insulation, leading to premature failures in electronic controllers, VSD boards and sensitive processing equipment.

- Harmonics from non-linear loads: VSDs on pumps and conveyors, solar inverters and electronic ballasts inject distortion that heats transformers, destabilises automation systems and triggers protective trips.

- Complete loss of supply: Exposed rural lines and limited network redundancy can black out operations. Irrigation controllers, cold storage and livestock systems need ride-through capability or orderly shutdown to prevent product loss.

How We Diagnose (and de-risk) Your Operation

- Discovery and data: We review your electrical infrastructure, load schedules (seasonal peaks, irrigation cycles), recent outages and utility penalty notices.

- Measure what matters: Portable power quality analysers capture voltage, current, PF, THD (V/I), sags, swells and transients across key feeders during representative operating conditions (pump starts, pivot rotation, processing shifts, solar generation peaks). That evidence builds the business case and shows us exactly where to intervene.

- Pinpoint root causes: We correlate symptoms to sources (e.g. 5th/7th harmonics from bore pump VSDs; low PF from old induction motors on conveyors; voltage drop on long submersible cable runs; grid interaction issues with solar arrays).

- Actionable plan: You'll receive a comprehensive report with priorities ranked by impact, ROI projections and a staged rollout that respects planting, harvest and processing schedules.

Next step:

Book a Power Quality Audit for an in-depth analysis and report mapping the critical improvements, sequence of works, and modelled ROI before you commit.

Solutions That Fit Agricultural Conditions

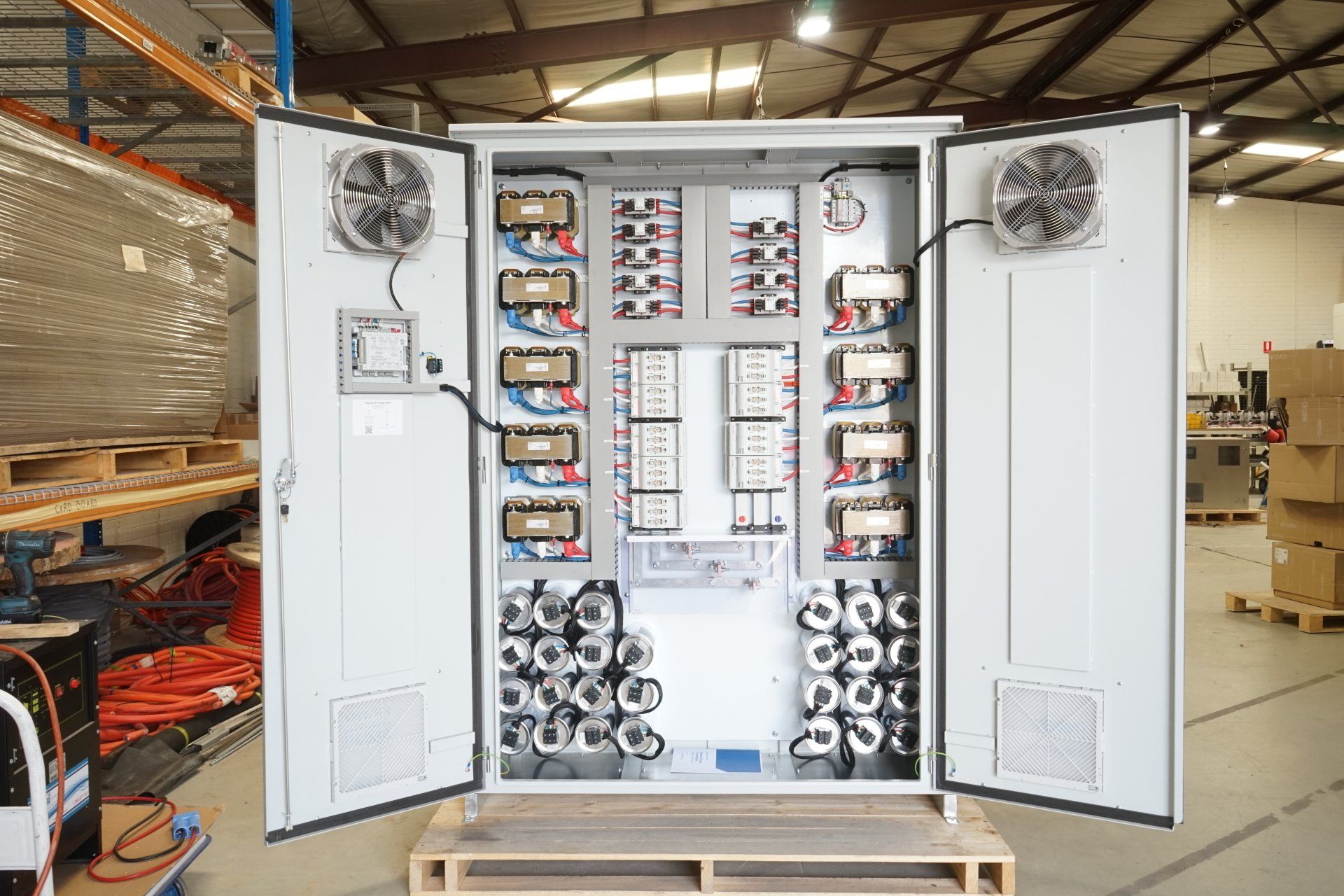

Designed and manufactured in Moorabbin VIC, our systems are engineered for dusty, humid, high-temperature environments common in Australian agriculture. Most farming operations benefit from:

Custom-built power factor correction units to lift power factor (typically to 0.95-0.99), reduce kVAr demand and eliminate utility penalties that erode profitability.

Dynamic harmonic mitigation to clean up voltage waveforms, reduce equipment stress and prevent costly trips during critical irrigation or processing windows.

Like any piece of machinery, your Power Factor Correction System needs to be regularly maintained and serviced to ensure optimal performance levels are maintained and keep the system doing the job it was installed to do. Find out why we are trusted by the biggest Australian brands for over 30 years to keep their PFC working in optimal conditions.

Is your business suffering from unexplained electrical faults, failures or power spikes? A power quality audit will identify issues and give us the data we need to design an appropriate solution for your business. Discover how a Power Quality Audit can provide you with the data and information you require to make informed decisions about Power Quality management on your site.

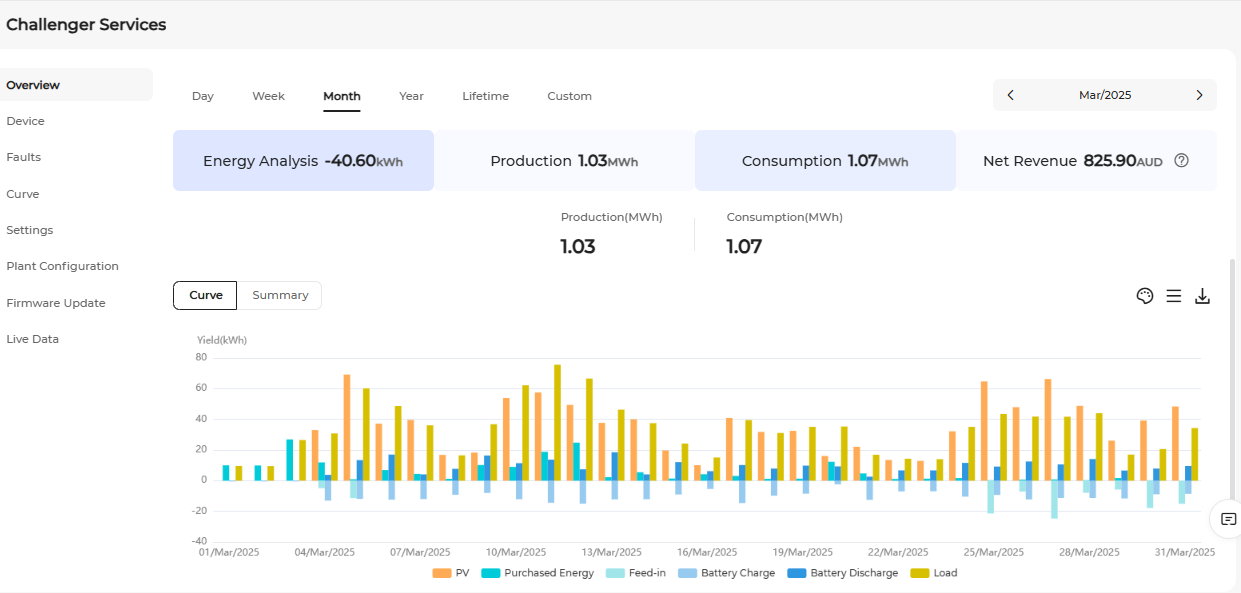

A well-designed solar system will help you reduce your electricity bill and reliance on coal-generated grid electricity. With energy prices at an all-time high, there is no better time to start a conversation with us about installing solar power system in your business.

What Outcomes Can You Expect?

While every operation is different, typical results after an audit-led implementation include:

- Power factor lifted to utility targets (commonly 0.95–0.99 on grid supply; tailored targets for hybrid solar-diesel systems)

- THDi reduced substantially on problem circuits, improving system stability and equipment lifespan

- Fewer nuisance trips on VSD-driven pumps and conveyors during critical operating periods

- Lower demand charges and penalty avoidance, with many operators seeing payback within 18–30 months

- Improved solar inverter performance and grid compliance on mixed-source systems

How Quality Energy Helped Covino Farms Cut Electricity Costs in Longford, Victoria

Covino Farms was dealing with an inefficient electrical network and low power factor that was driving up their electricity bills. Network demand charges were eating into margins, and the farm needed a solution that would fit their tight equipment space and allow easy maintenance access.

We conducted an in-depth power quality study, then designed and manufactured a custom 450 kVAr Power Factor Correction unit at our Moorabbin factory. The unit featured an open equipment design for straightforward maintenance, minimal depth to suit their constrained location, and low heat stress construction for reliable operation in agricultural conditions.

Power factor improved significantly after installation, cutting network demand charges and delivering ongoing savings on electricity costs. The custom design meant the unit integrated seamlessly into their existing infrastructure without disruption to farm operations.

Equipment We Frequently Support on Agricultural Sites

- Bore pumps (electric submersible and surface-mounted)

- Centre pivot and lateral move irrigation systems

- Submersible pumps and variable speed pump drives

- Conveyors (grain handling, packhouse sorting)

- Cold storage and blast freezer compressors

- Dairy shed vacuum pumps and milk cooling systems

- Grain dryers and aeration fans

- Processing equipment (graders, washers, packaging lines)

- Livestock ventilation and climate control systems

- Solar inverter arrays and battery storage systems

- Standby and prime power diesel generators

Frequently Asked Questions

What power factor should we target on a grid-connected farm?

Most agricultural operations aim for 0.95–0.99 to avoid demand charges and maximise equipment efficiency. Your target should depend on your network provider's tariff structure and equipment profile.

Can Active Harmonic Filters and PFC work together on the same system?

Yes, when engineered correctly. AHF handles dynamic harmonics from VSDs and inverters; PFC improves power factor. Proper coordination and filter tuning prevents resonance issues.

The other option is to use a hybrid system that combines Static Var Generator (SVG) and Active Harmonic Filter (AHF) technology within the one unit.

This system uses real-time monitoring and control via microprocessors and IGBTs, allowing it to dynamically correct power factor and mitigate harmonic distortion simultaneously. The result is optimal power factor performance and reduced harmonic levels in real time.

We run solar during the day and grid at night. Does this complicate power quality correction?

Not when designed as an integrated system. We account for solar inverter harmonics, reverse power flow characteristics and day-night load transitions to ensure seamless operation across all modes.

Our bore pumps trip randomly during summer peaks. Is this a power quality issue?

Likely yes. Summer peaks often coincide with voltage sag from network loading and high inrush from multiple pump starts. We can measure and confirm, then design ride-through or voltage support solutions.

Will power quality equipment handle the dust and heat on our property?

Our equipment is IP-rated for agricultural environments and can be specified with enhanced cooling, filtration and corrosion protection for high-dust, high-temperature locations.

How quickly will we see a return?

PFC delivers measurable savings from the first full billing cycle after commissioning. Many agricultural clients achieve full payback within 18–30 months through penalty elimination, reduced demand charges and improved equipment reliability.

Why Partner With Quality Energy?

Quality

Premium quality components sourced from accredited suppliers. All solutions are manufactured in our factory at Moorabbin and go through rigorous Factory Acceptance Testing (FAT) before installation.

Safety

Safety is our top priority. Our technicians and contractors undergo regular professional and safety training to ensure the safety of our clients and your property.

Efficiency

Our in-house engineering team, electrical technicians and operations team work together using electrical data that is unique to your energy use profile to deliver your Power Quality and energy efficiency solutions on time, on budget.

Recent Projects

Get in Touch With the Quality Energy Team Today

Put our power quality expertise to work on your farm. Speak with our engineers about your operation and next steps.