Power Factor Correction Sydney: Australian-Made Solutions for Commercial & Industrial Sites

Sydney businesses face some of Australia's highest electricity costs, with kVA demand charges and power factor penalties adding thousands to quarterly bills. Quality Energy manufactures custom power factor correction equipment right here in Australia, designed to eliminate excess demand charges, improve electrical efficiency, and extend the operational life of your infrastructure.

From Parramatta's industrial estates to manufacturing facilities in Auburn, food processing plants in Smithfield, and data centres across the CBD, our ECO and MOD PFC systems deliver measurable savings for businesses operating across Greater Sydney and regional NSW.

Why Sydney Businesses Need Power Factor Correction

Operating with a poor power factor inflates your electricity bills through demand charges and efficiency penalties. It forces your electrical system to draw more current than necessary, creating excess heat, accelerating wear on switchgear and transformers, and limiting available capacity across your entire network.

For Sydney's energy-intensive industries including food manufacturing, cold storage, warehousing, materials processing, and heavy industrial operations, the cost of inefficiency compounds quickly. Many sites are unknowingly paying for unused capacity and pushing their infrastructure closer to its operational limits.

The Real Cost of Low Power Factor in Sydney

- Demand charge penalties: Energy retailers impose kVA-based charges when your power factor drops below acceptable thresholds, directly increasing what you pay per billing period

- Wasted network capacity: Poor power factor reduces how much useful power your existing cables, switchboards, and transformers can deliver, often triggering expensive infrastructure upgrades

- Reduced equipment lifespan: Excess current creates additional heat stress on electrical components, increasing maintenance frequency and accelerating replacement cycles

- Voltage instability: Low power factor can cause voltage fluctuations that disrupt sensitive manufacturing equipment and automated systems

- Higher carbon emissions: Drawing more current to achieve the same work output increases your site's overall energy consumption and environmental impact

If your most recent power bill shows a kVA demand charge or lists a power factor penalty, your Sydney facility is likely overpaying for electricity every month. Reactive power compensation through correctly sized PFC equipment addresses this at the source.

Australian-Made PFC Equipment for Every Sydney Industry

Quality Energy designs and manufactures two distinct PFC system configurations, each engineered to match different operational requirements, budget constraints, and site specifications across Sydney's diverse industrial landscape.

ECO Power Factor Correction:

Cost-Effective Efficiency for Sydney SMEs

Our ECO design delivers reliable reactive power compensation at the lowest possible upfront cost, making it ideal for Sydney businesses seeking immediate efficiency improvements without extensive capital outlay. This streamlined configuration mounts all components directly onto the cabinet backing plate, reducing complexity while maintaining thermal management and operational reliability.

Strategic component placement maximises performance:

- Capacitors positioned at the bottom of the backing plate where ambient temperature remains lowest

- Low-loss harmonic blocking reactors mounted mid-side, isolating their heat signature from temperature-sensitive components

- All live conductors fully insulated and rated IP2X for maximum safety and protection

- Compact footprint suitable for sites with limited electrical room space

ECO PFC systems suit Sydney sites requiring:

- Reactive power compensation up to 400kVAr

- Simple installation with minimal commissioning time

- Low maintenance requirements and straightforward serviceability

- Budget-conscious investment with fast payback periods

- Reliable performance for moderate to high electrical loads

The ECO configuration is effective for Sydney's food processing operations, light manufacturing facilities, commercial cold storage, warehousing and distribution centres, and retail operations with significant refrigeration loads.

Modular Power Factor Correction:

Scalable Premium Systems for High-Demand Sydney Sites

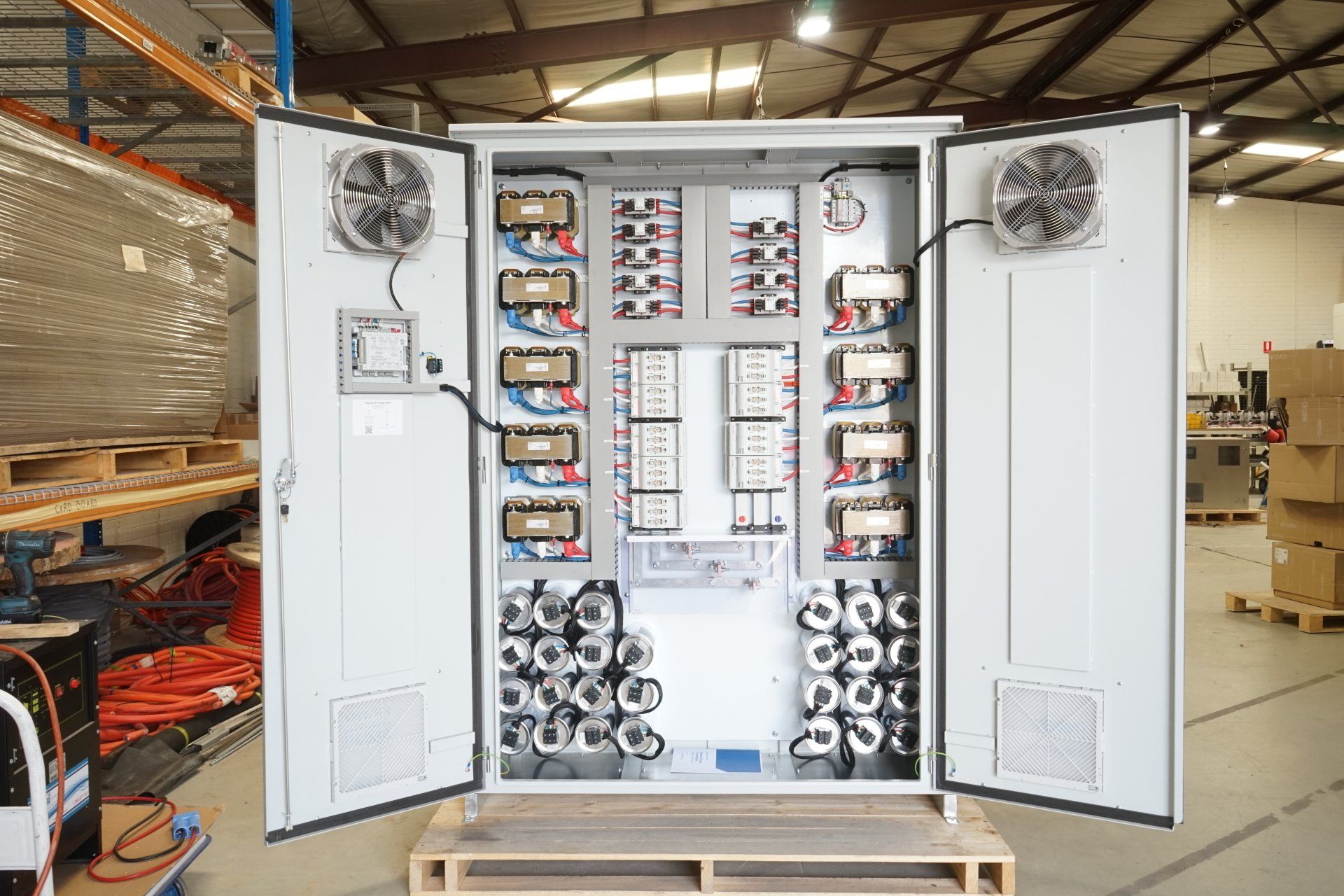

When Sydney facilities demand higher correction capacity, operational flexibility, or future scalability, our MOD PFC equipment provides premium performance with expandability. Built with individual, fully segregated modules installed on slide-out trays, this configuration supports systems from 50kVAr to beyond 1000kVAr.

Advanced engineering features include:

- Fully segregated modular sections for improved safety and simplified troubleshooting

- Widened reactor compartments improving airflow and thermal performance

- Slide-out trays enable fast servicing without extended downtime

- Modular architecture allowing capacity increases as electrical demand grows

- Enhanced component accessibility for maintenance and upgrades

MOD PFC systems suit Sydney operations requiring:

- Reactive power correction exceeding 400kVAr

- Room for future capacity expansion as production increases

- Minimal downtime during maintenance or servicing

- Premium performance in demanding electrical environments

- Long-term investment protection through scalable design

The MOD configuration suits Sydney's heavy manufacturing sector, large-scale food production facilities, mining and materials processing operations, major data centres and infrastructure, commercial high-rise buildings, and any industrial site planning significant growth.

How Power Factor Correction Can Transform Your Operations

Installing engineered PFC equipment delivers immediate and ongoing financial benefits and improves electrical system performance and reliability across your Sydney facility. Here’s how:

Direct Cost Reduction

Reactive power compensation eliminates kVA demand charges and power factor penalties that many Sydney businesses accept as unavoidable. For sites currently operating below 0.90 power factor, installing PFC equipment can generate significant annual savings. Read how we

helped Sunrice save approximately $70,000 per annum with a custom built power factor correction unit.

Increased Network Capacity

Poor power factor forces cables, transformers, and switchgear to carry significantly more current than necessary to deliver the same useful power. Correcting this inefficiency frees substantial capacity across your existing infrastructure, often eliminating the need for electrical upgrades.

Many Sydney facilities discover they can expand production, add new equipment, or accommodate increased loads without installing larger transformers, upgrading main switchboards, or running additional cable infrastructure. This deferred capital expenditure often represents six-figure savings.

Extended Equipment Life

Reducing current flow through your electrical system decreases heat generation across all components. Lower operating temperatures directly extend the functional lifespan of motors, cables, contactors, transformers, and switchgear while reducing maintenance frequency and the risk of premature failure.

We recently helped Visy

reduce equipment and switchboard temperatures by 43%.

For industrial operations where unexpected electrical failures trigger production downtime, this improved reliability provides value well beyond the immediate energy savings.

Enhanced Voltage Stability

Power factor correction improves voltage regulation across your facility, reducing fluctuations that can disrupt sensitive manufacturing equipment, automated control systems, and electronic loads. This stability is important for Sydney sites running precision machinery, automated production lines, or temperature-critical processes.

Environmental & Sustainability Benefits

By reducing total current draw and improving system efficiency, PFC equipment lowers your site's overall energy consumption and associated carbon emissions. For businesses working toward sustainability targets or seeking

Green Star certification, documented efficiency improvements through power factor correction provide measurable environmental credentials.

Quality Energy PFC Systems Are Manufactured to Australian Standards for Proven Reliability

Every power factor correction system we manufacture undergoes comprehensive factory testing before delivery to your NSW site. Our quality assurance process includes functional verification, thermal performance validation, and stringent safety assessments ensuring your equipment performs exactly as specified from initial commissioning.

Compliance & Standards

All Quality Energy PFC units are engineered and manufactured in Melbourne to meet or exceed relevant AS/NZS standards including AS/NZS 3000, 3947, IEC 60871 & IEC 831. We work directly with your local supply authority to ensure every system complies with network requirements, eliminating compliance issues and ensuring seamless integration with existing electrical infrastructure.

Commissioning & Validation

Our technical team handles on-site commissioning at your facility (regardless of where in Sydney or regional NSW you are located). We calibrate the PFC system to match your actual load profile and validate performance under real operating conditions. This hands-on approach guarantees the equipment delivers projected efficiency improvements and cost savings from day one.

Ongoing

Support

Power factor correction equipment requires minimal maintenance when correctly specified and installed. Our systems are designed for long operational life with straightforward serviceability. For Sydney businesses requiring ongoing support, we provide comprehensive annual

power factor correction servicing ensuring your PFC investment continues delivering peak performance year after year.

Qantas Sydney Airport – 2,000kVAr Installation Slashes Demand Charges

When demand charges represented 60% of Qantas' total energy bill at Sydney International Airport, Quality Energy designed and installed over 2,000kVAr of custom power factor correction systems across multiple airport sites. The installation dramatically reduced demand charges while managing rising electricity costs for one of Australia's most critical aviation operations.

Visy Packaging & Recycling – 26.65MVAr Across East Coast Facilities

For over 20 years, Quality Energy has provided power factor correction and harmonic filtering solutions to Visy facilities including major Sydney operations in Smithfield and Warwick Farm. Our comprehensive installation totalling 26.65MVAr across multiple sites has reduced switchboard temperatures by up to 43%, improved system capacity, and delivered hundreds of thousands of dollars in annual demand charge savings.

Warning Signs Your Sydney Site Needs PFC Equipment

Most businesses don't realise they're being penalised for a poor power factor until they look at their electricity bills in detail. Here’s what else to look for that could indicate a need for power factor correction at your facility:

- Your power bill lists kVA demand charges separate from kWh consumption charges or your electricity costs seem disproportionate to your actual usage

- Your electrical system frequently approaches its rated capacity limits

- You've been advised you need infrastructure upgrades to add new equipment

- Voltage fluctuations affect production quality or equipment performance

- Your motors, transformers, or switchgear run noticeably hot

- Circuit breakers trip occasionally despite loads being within rated capacity

Any of these indicators suggests that your Sydney operation would benefit from a

professional power quality audit and, potentially, correction equipment. A power quality audit surveys your real-time power usage and identifies the root cause of your power quality issues.

Quality Energy begins every project with a comprehensive assessment of your existing electrical infrastructure, load characteristics, and current power factor performance. This analysis determines which PFC configuration delivers the best return on investment.

Our Sydney service includes:

- Detailed power quality assessment and monitoring

- Load profile analysis and power factor measurement

- Financial modelling showing projected savings and payback periods

- Custom equipment specification and design

- Factory testing and quality assurance

- Professional installation and commissioning

- Performance validation and documentation

- Ongoing support and maintenance programs

From initial consultation through final commissioning, we ensure your PFC investment delivers the efficiency improvements and cost reductions your Sydney business needs.

Contact our team to discuss your site's requirements, arrange a power factor assessment, or learn more.

Serving Sydney and all of NSW including: Parramatta, Auburn, Smithfield, Wetherill Park, Silverwater, Ingleburn, Rydalmere, Blacktown, Penrith, Liverpool, Campbelltown, Wollongong, Newcastle, Central Coast, and regional NSW.