Power Factor Correction Brisbane – Reducing Energy Costs for Queensland Industry

Queensland's subtropical climate and growing industrial sector create unique electrical challenges. Air conditioning loads, refrigeration systems, and manufacturing equipment drives substantial demand charges for Brisbane businesses. Quality Energy manufactures power factor correction equipment in Australia designed to eliminate these excess costs while improving system efficiency and equipment longevity.

From Brisbane's industrial corridors in Acacia Ridge and Rocklea to manufacturing operations in Yatala and food processing facilities throughout Southeast Queensland, our custom ECO and Modular PFC systems deliver proven cost savings and performance improvements.

The Hidden Cost of Poor Power Factor in Brisbane

Queensland energy tariffs penalise inefficiency through kVA-based demand charges that many businesses struggle to understand. When your facility's power factor drops below desired levels, you're billed for both useful power consumed and total apparent power drawn from the grid.

This difference might seem technical, but the financial impact can be substantial. A Brisbane manufacturing facility operating at 0.85 power factor with 400kW demand can pay $40,000-$60,000 annually in excess demand charges compared to the same facility operating at corrected 0.95+ power factor. Larger operations face proportionally higher penalties.

Beyond direct cost impacts, poor power factor creates operational problems for Queensland businesses:

- Thermal stress in hot climates: Brisbane's subtropical temperatures mean electrical equipment already operates in challenging thermal conditions. Excess current from poor power factor generates additional heat, accelerating component degradation and increasing cooling requirements

- Capacity constraints during peak demand: Southeast Queensland's summer peaks put pressure on electrical infrastructure. Poor power factor reduces available capacity exactly when facilities need it most

- Cooling system inefficiency: Air conditioning represents a major load for Brisbane operations. Poor power factor makes these systems draw more current, compounding both energy costs and thermal stress

- Network limitations: Many Brisbane industrial areas operate near distribution capacity limits. Poor power factor exacerbates these constraints, sometimes triggering mandatory infrastructure upgrades

- Equipment reliability issues: High ambient temperatures combined with excess current create perfect conditions for premature equipment failure, increasing maintenance costs and downtime risk

Addressing power factor inefficiency delivers both immediate cost savings and long-term operational benefits.

Warning Signs Your Brisbane Facility Needs Power Factor Correction Equipment

Most businesses don't scrutinise electricity bills carefully enough to identify power factor penalties hiding within complex tariff structures. These charges often appear as unavoidable costs rather than inefficiencies that correction equipment can eliminate.

- Your power bills show kVA demand charges separate from kWh consumption

- You're charged power factor penalties or efficiency-related fees

- Your electrical system operates near its rated capacity

- You've been advised infrastructure upgrades are necessary for expansion

- Voltage fluctuations affect sensitive equipment or production quality

- Electrical equipment runs noticeably hot or requires frequent maintenance

- Circuit breakers trip despite operating within rated capacity

- Your facility runs substantial air conditioning, refrigeration, or motor loads

- Your recent energy costs have increased disproportionately to production

Any combination of these indicators suggests a power quality survey would be beneficial. This determined the exact cause of the power quality issues and what correction equipment is required.

Quality Energy Manufactures Power Factor Correction Equipment Built for Queensland Conditions

Quality Energy custom manufactures two power factor correction configurations, each designed to address different capacity requirements, budgets, and operational needs across Brisbane's diverse industries.

ECO PFC Equipment – Reliable Correction at Competitive Pricing

Our ECO design delivers effective reactive power compensation without unnecessary complexity or cost. This streamlined configuration focuses on essential performance while maintaining critical thermal management.

Effective for Brisbane's food industry, logistics operations, light manufacturing, and commercial facilities where straightforward power factor issues require cost-effective solutions with minimal maintenance demands.

Climate-conscious thermal design:

- Capacitors positioned at the cabinet's lowest point where temperature remains most stable

- Harmonic blocking reactors mounted strategically to isolate their heat generation from temperature-sensitive components

- Optimised internal airflow managing heat dissipation in warm ambient conditions

- All live conductors protected with IP2X-rated insulation

- Compact design suited to facilities with limited electrical room space

Best suited to:

- Operations requiring up to 400kVAr of reactive power compensation

- Food processing and cold storage facilities with consistent refrigeration loads

- Manufacturing operations with moderate to high motor loads

- Warehousing and distribution centres throughout Southeast Queensland

- Commercial facilities seeking rapid return on capital investment

- Businesses prioritising proven reliability over advanced features

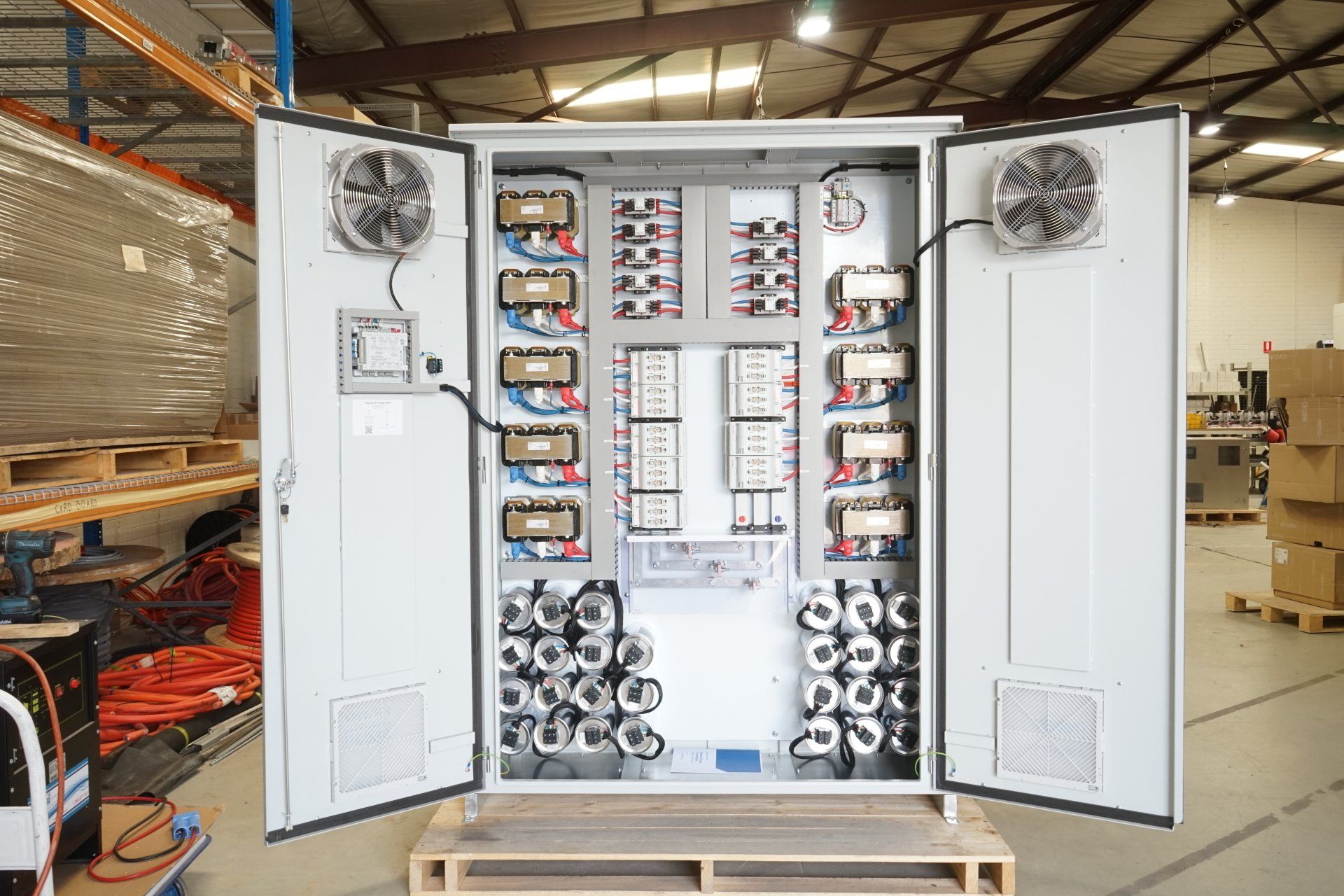

Modular PFC Equipment – Premium Performance for High-Demand Operations

When Brisbane facilities require correction capacity exceeding 400kVAr, anticipate future growth, or operate in demanding environments, our modular configuration provides premium engineering with expandability and enhanced serviceability.

Advanced features for demanding applications:

- Fully segregated modular construction providing superior safety and thermal isolation

- Slide-out service trays enabling rapid component access and replacement

- Widened reactor compartments maximising airflow and heat dissipation

- Modular architecture supporting capacity increases as operational needs evolve

- Enhanced monitoring systems for optimal performance management

Best suited to:

- Heavy manufacturing requiring correction beyond 400kVAr capacity

- Large-scale food processing and agricultural facilities

- Mining support operations and materials processing

- Cold storage and logistics hubs serving regional Queensland

- Any operation valuing minimal downtime for maintenance or servicing

- Facilities planning significant expansion or production increases

The modular configuration represents strategic investment in long-term electrical performance, with scalability. Your PFC system adapts as Queensland's growing economy drives business expansion and increased energy demand.

What Brisbane Businesses Achieve Through Power Factor Correction

Installing engineered PFC equipment delivers immediate financial returns and addresses operational challenges.

Immediate Demand Charge Elimination

Correcting power factor to 0.95 or above removes kVA-based penalties from your electricity bills. These savings begin immediately upon commissioning and continue throughout the system's operational life. With typical payback periods between 18-36 months, power factor correction represents one of the highest-return efficiency investments available to Queensland businesses.

Releasing Network

Capacity

Reducing reactive current through your electrical distribution frees capacity across existing infrastructure. For Brisbane businesses operating near their electrical limits or planning expansion, this efficiency gain often eliminates transformer upgrades, switchboard replacements, or additional cable installations.

Improved Equipment Performance in Queensland's Climate

Reduced thermal stress extends operational life for motors, cables, contactors, transformers, and switchgear while simultaneously decreasing maintenance frequency and failure risk. For operations running critical refrigeration or continuous production, this improved reliability translates to reduced downtime risk and associated costs.

Improved Cooling

Efficiency

Air conditioning represents a major electrical load for Brisbane facilities year-round. Power factor correction improves the efficiency of HVAC systems by reducing total current draw, which simultaneously decreases the heat load your cooling systems must manage.

Voltage Stability & Production Quality

Fluctuations can disrupt production equipment, automated systems, or temperature-critical processes. Power factor correction stabilises voltage regulation across your facility. If you run precision machinery, automated production lines, or processes requiring consistent environmental control, you’re likely to benefit from power factor correction equipment.

ESG

Benefits

By reducing total energy consumption and improving system efficiency, PFC equipment lowers your facility's carbon emissions. For Queensland businesses pursuing sustainability objectives or working toward emissions reduction commitments, documented efficiency improvements through power factor correction provide measurable environmental outcomes.

Brisbane Industries We Serve

Quality Energy provides custom power factor correction solutions to B2B clients across Brisbane and Southeast Queensland's industrial sectors:

- Food Processing: Meat processing, seafood, dairy, beverages, bakeries, prepared foods

- Packaging & Recycling:Glass recycling, materials recovery, cardboard manufacturing, recycling operations

- Cold Chain & Logistics: Cold storage, refrigerated warehousing, distribution centres, transport hubs

- Mining & Resources Support: Equipment manufacturing, materials processing, workshop operations

- Agricultural Processing: Grain handling, sugar milling, cotton ginning, produce packing

- Fabrication: Metal fabrication, plastics processing, building materials, industrial equipment

- Commercial Buildings: High-rise offices, shopping centres, hospitality facilities with major HVAC loads

- Water & Infrastructure: Pumping stations, treatment facilities, municipal operations

- Pharmaceutical & Medical: Manufacturing, processing, laboratory facilities

Regardless of industry, if your Brisbane site operates significant inductive loads, runs substantial cooling equipment, or shows concerning demand charges on power bills, custom power factor correction represents a high-return efficiency investment.

We’ve Helped Industries Across Queensland Improve Their Power Factor

Newscorp Brisbane Print Centre – 3,500kVAr Across Six Substations

When Energex changed Newscorp's tariff structure and began penalising their poor power factor, Quality Energy installed 3,500kVAr of custom power factor correction across six substations at their Brisbane Print Centre. This reduced network demand charges and improved power factor performance. Read the full

Newscorp Brisbane case study.

David Moss Corporation (DAMOS) Geebung – $350,000 Transformer Upgrade Avoided

Facing a $350,000+ transformer upgrade to add new equipment, DAMOS instead invested in Quality Energy's 1.7MVAr power factor correction solution for their Geebung facility. This improved power factor from an extremely poor 0.63 to 0.99 and saved over $8,500 per month in demand charges with an 18-month ROI. Read the full

DAMOS case study.

Visy Packaging & Recycling – 20+ Year Partnership, 26.65MVAr Across East Coast

For over 20 years, Quality Energy has partnered with Visy across their east coast operations including Queensland facilities in Yatala and Murarrie. We have installed 26.65MVAr of power factor correction and active harmonic filters that reduced switchboard temperatures by up to 43%, delivering hundreds of thousands of dollars in annual demand charge savings. Read the full

Visy case study.

Quality Energy PFC Systems: Australian Engineering Excellence & Standards Compliance

Every Quality Energy power factor correction system is designed and manufactured in Australia to meet or exceed all relevant AS/NZS electrical standards. Our comprehensive approach ensures your equipment operates safely and reliably in Queensland's demanding environment.

Pre-Delivery

Testing & Verification

Before shipping to your Brisbane facility, each PFC system undergoes rigorous factory testing including functional verification, thermal performance validation under load, and comprehensive safety assessments.

This quality assurance process ensures your equipment meets specifications and operates reliably from commissioning onward.

Professional Commissioning in Brisbane

Our technical team handles commissioning at your Southeast Queensland site, calibrating the PFC system to your actual load profile and validating performance under real operating conditions. This includes detailed power factor measurement, harmonic analysis where required, and verification of demand charge reduction.

We coordinate directly with your supply authority to ensure full compliance with local network requirements, eliminating potential compliance issues and ensuring seamless integration with existing electrical infrastructure.

Ongoing Support Throughout Queensland

Properly designed and installed PFC equipment requires minimal maintenance over its operational life. Our systems are engineered for long-term reliability in Australian conditions with straightforward serviceability when needed.

For Brisbane businesses requiring ongoing support, we provide comprehensive maintenance programs ensuring optimal performance year after year.

How to Get Started: Book a Power Factor Survey for Your Brisbane Site

Every Quality Energy project begins with a comprehensive assessment of your existing electrical infrastructure, load characteristics, and current power factor performance. This analysis determines exactly how much reactive power compensation your facility requires and identifies which system configuration delivers optimal return on investment.

Our complete Southeast Queensland service includes:

- Detailed power quality assessment and monitoring over representative operating periods

- Load profile analysis accounting for seasonal variations in Brisbane's climate

- Financial modelling demonstrating projected savings and investment payback

- Custom equipment design and specification for your exact requirements

- Comprehensive factory testing and quality assurance

- Professional installation coordinated with your operational schedule

- Commissioning and performance validation under actual load conditions

- Documentation and compliance verification for supply authority requirements

- Ongoing support and maintenance programs as required

From initial consultation through commissioning and beyond, we ensure your PFC investment delivers the efficiency improvements and cost reductions your Brisbane business requires.

What our customers say

Contact Quality Energy Today for Power Factor Correction Units Made for Brisbane Industries

Stop paying unnecessary demand charges and power factor penalties. Quality Energy's Australian-manufactured PFC equipment eliminates inefficiency, reduces electricity costs, and protects your electrical infrastructure for long-term reliable operation.

Contact our team to discuss your facility’s requirements, arrange a comprehensive power factor assessment, or learn how custom correction equipment can improve your electrical system performance.

We service Brisbane and all of Southeast Queensland including: Acacia Ridge, Rocklea, Yatala, Coopers Plains, Archerfield, Salisbury, Darra, Richlands, Eagle Farm, Pinkenba, Gold Coast, Sunshine Coast, Toowoomba, Ipswich, and regional Queensland.