Power Factor Correction Adelaide: Supporting South Australian Manufacturing Excellence

South Australia's manufacturing sector and renewable energy landscape create unique electrical challenges, with demand charges and power factor penalties significantly impacting operational costs for Adelaide businesses. Quality Energy manufactures custom power factor correction equipment in Australia designed to eliminate these excess charges while improving system stability and equipment reliability.

From Adelaide's northern industrial suburbs in Wingfield and Edinburgh Parks to manufacturing operations in Lonsdale and food processing facilities throughout South Australia, our custom ECO and Modular PFC systems deliver proven efficiency gains and cost reductions.

Does Your Adelaide Facility Need Power Factor Correction?

Many businesses don't examine their electricity bills carefully enough to identify power factor penalties and demand charges hiding within complex tariff structures. These costs often appear as unavoidable business expenses rather than inefficiencies that correction equipment can eliminate.

Indicators Your Adelaide Site Would Benefit from PFC

- Your electricity bills show separate kVA demand charges

- You're charged power factor penalties or low efficiency fees

- Your electrical system operates near its rated capacity limits

- You've been advised infrastructure upgrades are necessary for expansion

- Voltage fluctuations affect equipment performance or product quality

- Electrical equipment runs noticeably hot or requires frequent maintenance

- Circuit protection devices trip despite operating within rated capacity

- Your facility runs substantial motor loads, compressors, or inductive machinery

- Your energy costs seem disproportionate to your actual production output

Any combination of these factors suggests your Adelaide operation would benefit from professional power factor assessment and likely correction equipment installation.

South Australian Industries We Support

Quality Energy provides custom power factor correction solutions to B2B clients across Adelaide and South Australia's industrial sectors:

Advanced Manufacturing: Defence industry, automotive components, precision engineering, industrial equipment

Food and Beverage Production: Wine production, brewing, food processing, commercial bakeries, dairy operations

Packaging & Recycling: Paper processing, materials recovery, recycling operations

Mining and Resources: Mineral processing, materials handling, workshop operations, equipment manufacturing

Agricultural Processing:

Grain handling, livestock processing, produce packing, vineyard operations

Metal Fabrication & Engineering: Steel fabrication, machining, surface treatment, component manufacturing

Water and Infrastructure: Pumping stations, treatment facilities, desalination, municipal operations

Warehousing & Logistics: Distribution centres, cold storage, transport operations

Commercial Buildings: High-rise offices, retail centres, hospitality facilities

Healthcare: Hospitals, operating theatres, imaging suites, pathology labs, sterilisation, HVAC/air-handling, UPS/generator-backed systems

Regardless of industry, if your Adelaide facility operates significant inductive loads, runs continuous processes, or shows concerning demand charges on power bills, custom power factor correction likely represents a high-return efficiency investment.

Quality Energy are Power Factor Correction Equipment Manufacturers Engineering Systems for South Australian Industry

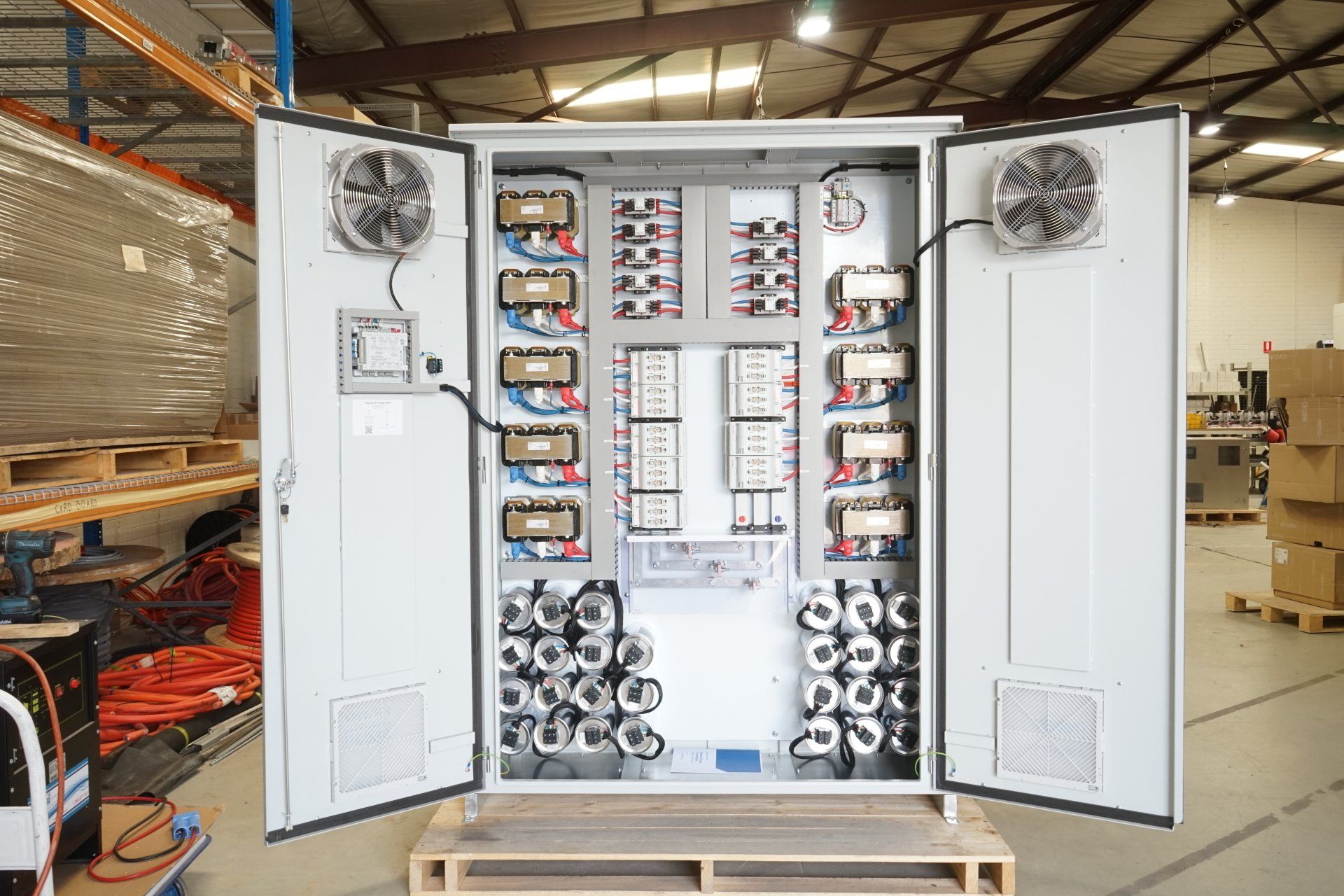

We manufacture two distinct power factor correction systems, each designed to address specific capacity requirements, operational objectives, and budgets across Adelaide's diverse industrial sectors.

ECO PFC Systems – Effective Correction Without Unnecessary Cost

Our ECO configuration focuses on delivering reliable reactive power compensation at the most competitive price point. This streamlined design eliminates complexity while maintaining the thermal management and safety standards essential for long-term reliable operation.

Intelligent engineering principles:

Capacitors positioned at the cabinet's lowest point for optimal thermal conditions

Low-loss harmonic blocking reactors strategically mounted to isolate heat from critical components

Optimised airflow paths maintaining consistent operating temperatures

All live conductors protected with IP2X-rated insulation

Compact footprint suitable for facilities with limited electrical room space

Adelaide operations suited to ECO PFC:

Manufacturing operations requiring up to 400kVAr correction capacity

Food processing and beverage production with consistent motor loads

Warehousing and cold storage facilities serving SA's agricultural sector

Commercial operations seeking rapid return on capital investment

Sites with straightforward power factor issues requiring proven, reliable solutions

ECO systems suit Adelaide businesses prioritising cost-effectiveness and reliability. The simplified design reduces upfront investment and ongoing maintenance requirements while delivering robust performance for moderate to high electrical loads common in South Australian manufacturing.

Modular PFC Systems – Premium Engineering for Complex Applications

When Adelaide facilities require correction capacity exceeding 400kVAr, need operational flexibility, or anticipate future expansion, our MOD configuration provides premium engineering with modular scalability and enhanced performance characteristics.

Advanced design features include:

Fully segregated modular construction isolating individual correction stages for superior safety

Slide-out service trays enabling rapid component access without extended downtime

Enhanced reactor compartments with superior airflow and thermal management

Modular architecture supporting capacity additions as operational demands increase

Advanced monitoring and control systems for optimal performance management

South Australian operations benefiting from MOD PFC:

Heavy manufacturing requiring correction capacity beyond 400kVAr

Defence industry contractors and advanced manufacturing operations

Wine production and agricultural processing facilities planning expansion

Mining support operations and materials processing throughout SA

Any industrial site valuing minimal downtime during maintenance activities

Facilities requiring scalability to accommodate future growth

The modular configuration represents a strategic investment in electrical infrastructure performance, with scalability ensuring your PFC correction system adapts as South Australia's advanced manufacturing sector continues developing and expanding.

Commercial Power Factor Correction Helps South Australian Businesses Save Money

Installing Australian engineered power factor correction delivers immediate financial returns while simultaneously improving system reliability, extending equipment operational life, and creating capacity for business growth.

Eliminating Demand Charge Penalties

Correcting power factor to 0.95 or higher removes kVA-based demand charges and efficiency penalties from your electricity bills. For Adelaide manufacturing sites, this typically translates to annual savings between $25,000 and $120,000+ depending on facility size, operating hours, and current power factor performance.

These savings commence the moment your PFC system is commissioned and continue throughout its operational lifespan. With typical payback periods between 18-36 months, power factor correction represents one of the most financially attractive efficiency investments available to South Australian businesses.

Releasing Electrical System Capacity

Reducing reactive current through your electrical distribution releases significant capacity across transformers, cables, and switchboards. This efficiency gain often eliminates the need for costly infrastructure upgrades when expanding production or adding new equipment.

Adelaide manufacturers planning facility growth often discover that power factor correction provides the additional capacity required without the cost of transformer replacements, switchboard upgrades, or new cable installations. For businesses facing supply authority constraints on available capacity, this improvement can prove essential for operational expansion.

Extended Equipment Lifespan

Lower current flow throughout your electrical system directly reduces thermal stress on every component. This translates to extended operational life for motors, contactors, cables, transformers, and protection devices while simultaneously reducing maintenance frequency and minimising failure risk.

For Adelaide industrial operations where electrical failures trigger production downtime and associated costs, this improved reliability represents substantial value beyond direct energy savings. Reducing unexpected maintenance events and extending component replacement cycles delivers both operational and financial benefits.

Enhanced Grid Stability Contribution

In South Australia's electrical environment with high renewable energy penetration, maintaining a good power factor across industrial loads contributes to overall grid stability. Some supply authorities recognise this benefit through incentive programs or preferential tariff structures for facilities maintaining high efficiency.

Beyond potential financial incentives, an improved power factor enhances voltage stability across your facility, reducing fluctuations that can affect production equipment performance, automated systems, or sensitive electronic loads.

Supporting Sustainability Objectives

By reducing total current draw and improving overall system efficiency, power factor correction lowers your facility's energy consumption and carbon emissions. For South Australian businesses pursuing environmental credentials or working toward emissions reduction targets, documented efficiency improvements through PFC provide measurable outcomes supporting sustainability reporting.

Quality Energy Manufactures PFC Equipment in Australia for Australian Standards

Quality Energy designs and manufactures every power factor correction system in our Melbourne factory to meet or exceed all relevant AS/NZS electrical standards. Our comprehensive quality assurance process ensures your equipment performs reliably from commissioning through decades of operation.

Factory Testing

& Quality

Assurance

Before shipping to your Adelaide or regional SA facility, each PFC system undergoes rigorous factory testing including functional verification, thermal performance validation, and comprehensive safety assessments.

This quality control process ensures your equipment meets specifications and operates safely under all anticipated load conditions.

Site

Commissioning & Validation

Our technical team handles commissioning at your site, calibrating the PFC system to your actual load profile and validating performance under real operating conditions. This includes detailed power factor measurement, harmonic analysis where required, and verification of demand charge reduction.

We coordinate directly with your supply authority to ensure full compliance with local network requirements and any specific SA network standards, eliminating potential compliance issues and ensuring seamless integration with existing infrastructure.

Ongoing Support Throughout South Australia

Properly specified and installed PFC equipment requires minimal maintenance over its operational life. Our systems are designed for long-term reliability with straightforward serviceability when required.

For Adelaide businesses requiring ongoing support, we provide comprehensive power factor correction servicing ensuring optimal performance throughout the system's operational life.

Some of Our Power Factor Correction Case Studies

Quality Energy has delivered custom power factor correction solutions to major manufacturers and processors across Australia, achieving substantial documented savings relevant to Adelaide's industrial sectors:

Boral x Quality Energy - 25 Years of Reliable Power Factor Performance

Facing persistent failures from outdated third-party PFC across multiple Victorian and South Australian sites, Boral turned to Quality Energy, starting a partnership that’s still going strong more than 25 years later. We’ve provided responsive servicing and maintenance on legacy power-quality gear and designed, manufactured, and installed custom PFC systems tailored to each facility.

The results: stronger power factor, improved operational efficiency, increased capacity, cooler switchboards (fewer failures, longer asset life), a smaller carbon footprint, and tens of thousands of dollars in annual demand-charge savings.

Santos - Fast Voltage-Dip Mitigation in the Cooper Basin

At a remote mine in South Australia’s Cooper Basin (home to Australia’s first large-scale onshore CO₂ capture and storage hub) Santos was battling disruptive voltage dips. Long cable runs (10–15 km) between large motors and the planned mitigation point amplified the issue, threatening critical infrastructure uptime.

Quality Energy engineered a site-specific fix: a custom 800 kVAr Static Var Generator (2 × 400 kVAr) paired with a tailored distribution board. The SVG delivers rapid, dynamic reactive support during motor starts, trimming kVAr demand and flattening current spikes to keep voltage steady.

The Results: steadier voltage, improved power quality, and greater operational resilience.

Your PFC Journey Starts Here

Every Quality Energy project begins with a comprehensive assessment of your electrical infrastructure, load characteristics, and current power factor performance. This power quality analysis determines exactly how much reactive power compensation your Adelaide facility requires and identifies which system configuration delivers optimal return on investment for your specific application.

Our complete South Australian service includes:

- Detailed electrical system assessment and power quality monitoring

- Load profile analysis and power factor measurement over representative operating periods

- Financial modelling demonstrating projected savings and investment payback

- Custom equipment design and specification for your exact requirements

- Comprehensive factory testing and quality verification

- Professional installation coordinated with your operational schedule

- Commissioning and performance validation under actual load conditions

- Documentation and compliance verification for supply authority requirements

- Ongoing support and maintenance programs as required

From initial consultation through commissioning and beyond, we ensure your PFC investment delivers the efficiency improvements and cost reductions your Adelaide or greater SA business requires.

What our customers say

Contact Quality Energy Today - Your Australian Power Factor Correction Equipment Suppliers

Eliminate power factor penalties and reduce electricity costs with Australian-engineered PFC equipment designed for industrial performance and long-term reliability in South Australian applications.

Contact our technical team to discuss your Adelaide facility's specific requirements, arrange a comprehensive power factor assessment, or learn how custom correction equipment can improve your electrical system efficiency and reduce operational costs.

Servicing Adelaide and all of South Australia including: Wingfield, Edinburgh Parks, Lonsdale, Regency Park, Gillman, Dry Creek, Cavan, Beverley, Port Adelaide, Kilburn, regional SA wine regions, Whyalla, Port Pirie, Mount Gambier, and throughout South Australia.